5 Things Buyers Must Know Before Purchasing a Handheld Laser Welding Machine

In the era of manufacturing upgrading, handheld laser welders have become a core tool for enterprises and workshops to improve efficiency and quality, thanks to their flexibility, precision, and high efficiency. However, the market is flooded with various models and configurations, making it easy for buyers to fall into the trap of “blindly pursuing high power” or “ignoring practical needs”. As a professional brand deeply engaged in laser welding technology research and development, STRION LASER has summarized five key points that buyers must clarify based on years of industry experience and product research and development logic, helping you make a cost-effective choice that truly matches your production needs.

1. Welding Capability Must Match Actual Workpiece Needs

The primary function of a handheld laser welding machine is to weld specific materials at specific thicknesses. Choosing excessive power often leads to unnecessary investment, while insufficient power directly limits welding efficiency and process stability. Therefore, before purchasing, buyers should clearly define two fundamentals: what materials are welded most often, and what is the maximum workpiece thickness.

STRION LASER’s product range covers power levels from 900W to 3000W, with each model positioned for a clear application range. For example, the LITE S30 (900W) is suitable for welding up to 3 mm aluminum alloy, stainless steel, and carbon steel, making it a practical choice for small workshops producing thin-sheet hardware and daily-use metal products.

The MASTER X50 (1500W) supports welding up to 5 mm aluminum alloy and carbon steel, meeting the needs of medium-sized manufacturers processing agricultural machinery parts and other medium-thickness components.

At the high end, the MASTER X80 (3000W) can complete single-pass welding of 10 mm carbon steel and 8 mm stainless steel, addressing heavy-duty applications such as large mechanical bases and structural components.

It is also important to note that welding capability is closely linked to the quality of core components. STRION LASER machines are equipped with high-power fiber laser sources that deliver stable beam quality, enabling reliable welding of high-reflective materials such as aluminum alloys. With an annual power attenuation rate of less than 1% and long-term power fluctuation controlled within 1%, consistent welding performance is maintained even after extended operation.

2. Focus on System Stability and Adaptability to Working Conditions

For production-oriented manufacturers, equipment stability directly affects output continuity and yield rate. The stability of a handheld laser welder depends not only on core components, but also on the overall system design and thermal management strategy.

STRION LASER integrates stability into the product architecture. All models are equipped with a dual-circuit refrigerant direct-cooling system, enabling continuous operation across a wide temperature range of –30°C to 60°C without overheating. Independent drive modules and an opto-electrical separation design further improve heat dissipation and reduce failure risks under long-duty operation.

In demanding workshop environments with dust and humidity, protection level is equally important. STRION LASER handheld laser welders feature IP5X dust protection and IPX3 water resistance, helping minimize downtime caused by environmental factors. The MASTER X series also supports armored integrated cables (5 m or 10 m), designed for frequent movement and harsh industrial conditions.

3. Evaluate Ease of Operation and Long-Term Maintenance Cost

In many workshops, operator skill levels vary, making ease of use a key factor in productivity. Complex operation increases training time and dependence on experienced welders, while maintenance cost becomes a long-term expense that should be considered before purchase.

STRION LASER optimizes both aspects through practical design. The self-developed K-series welding gun weighs only 390 g and features an ergonomic grip to reduce fatigue during extended use. Quick-change protective windows and focusing lenses allow accurate replacement without specialized technicians. Built-in process libraries with over 20 preset welding modes enable new operators to start working after basic training, reducing reliance on highly skilled labor.

Maintenance requirements are also minimized. Anti-spatter design and air-knife cleaning help keep optical components clean, extending lens service life. The non-QBH design eliminates alignment-related wear and reduces replacement costs. Combined with stable output and low failure rates, these features help control maintenance time and long-term operating expenses.

4. Confirm Expandability and Intelligent Integration Capability

As businesses grow, production needs often evolve from single welding tasks to multiple processes or from manual operation to automated manufacturing. For this reason, equipment expandability and intelligent compatibility should be evaluated early to avoid repeated investment later.

STRION LASER machines are designed with this flexibility in mind. All models provide digital and I/O interfaces that support not only welding, but also processes such as cleaning, cutting, and cladding—allowing one system to serve multiple applications. In terms of intelligent integration, the equipment supports multiple communication protocols and can be connected to robots and automated lines, fitting easily into different automation setups.

In practice, many small and medium manufacturers begin with manual handheld operation and later upgrade to automated production without replacing the machine. Intelligent parameter control and process monitoring further improve consistency and efficiency in batch production environments.

5. Verify Power Supply Requirements and System Compatibility

Power supply conditions and accessory compatibility are often overlooked, yet they directly affect whether the equipment can be used properly after installation. Before purchasing, buyers should confirm whether the workshop power supply matches the machine’s requirements and whether auxiliary equipment is fully compatible with the welder.

STRION LASER’s LITE S30 and LITE S40 operate on single-phase 220V, making them suitable for small workshops without three-phase power. The MASTER X series (1500W, 2000W, 3000W) requires three-phase 380V, and workshops should verify power capacity in advance. Rated input power ranges from 3000W to 10,500W, which should be matched to the site’s electrical load.

For system compatibility, STRION LASER offers dedicated wire feeders such as STR-WFS-A (single-wire) and STR-WFD-A (dual-wire), supporting 0.8–2.4 mm welding wire for stainless steel, carbon steel, and aluminum alloys. With adjustable feeding speeds from 25–150 cm/min, these accessories are designed to match different power levels and processes, helping ensure stable welding quality without integration issues.

Conclusion: Choose the Right Equipment to Multiply Productivity

Purchasing a handheld laser welding machine is not about choosing the highest power, but about making a decision based on materials, thickness, working conditions, and future production plans. A well-matched machine delivers stable output, higher efficiency, and long-term cost control.

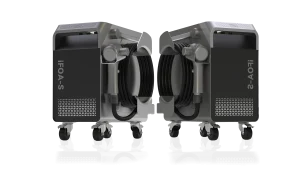

STRION LASER has built its handheld laser welding solutions around real production scenarios. From the cost-effective LITE S Series to the professional MASTER X Series, each model is designed with a clear purpose—combining reliability, ease of operation, and flexible expandability to support manufacturers at different stages of growth.

If you are still uncertain about which model fits your needs, visit www.strlaser-en.com for detailed specifications or contact +86-28-85812068. STRION LASER’s technical team is ready to provide practical, one-to-one guidance to help you select equipment that truly supports your production upgrade.