Aluminum and aluminum alloys, characterized by high strength, low density, and excellent corrosion resistance, are widely used in industries such as home appliances, construction, light industry, automotive, and aerospace. As industrially prevalent high-reflectivity metal materials, aluminum and its alloys pose unique challenges during welding due to their high thermal conductivity and strong oxidation tendencies. These characteristics often lead to porosity, slag inclusions, and workpiece deformation during welding processes. Additionally, the relatively high cost of aluminum further complicates operations, making sheet metal fabrication with these materials particularly challenging.

Laser welding is currently one of the most efficient and effective welding methods, with significant potential for industrial applications. Owing to its high energy density, small heat-affected zone, and minimal workpiece distortion, laser welding is increasingly being adopted by manufacturers in various industries to improve production efficiency and quality.

The combination of aluminum and laser welding seems like a perfect match at first glance. However, due to their conflicting characteristics, this pairing presents numerous challenges in practical welding operations. A handheld laser welder for aluminum can help address these challenges by providing precise control over heat input and minimizing the risk of common issues like oxidation and distortion, making it an ideal solution for welding aluminum and its alloys.

Compared to traditional welding methods, laser welding machines demonstrate superior performance when welding aluminum materials.

Taking handheld laser welders as an example, these devices have become a popular choice for thin aluminum sheet welding (typically ranging from 0.1mm to 5mm) thanks to their ease of use and stable operation. However, given the intrinsic properties and characteristics of aluminum, welding operations must carefully balance three key factors:

1. Low Laser Absorption and High Thermal Conductivity of Aluminum.

2. Aluminum’s Surface is Prone to Oxidation, Leading to Porosity and Hot Cracking.

3. Heat Distribution in the Welding Zone is Easily Affected by the Welding Environment, Making Arc Start and End Challenging.

Handheld laser welders achieve high-precision welding through focused high-density energy. Thanks to the high energy density of the laser source and the consistent weld quality, laser welding enables efficient processing, significantly improves work efficiency, and reduces energy costs.

STR-HW Series Handheld Laser Welder’s outstanding performance in aluminum welding

Based on extensive testing and validation by our R&D team addressing the aforementioned welding operation balance points, the STR-HW Series like 700w handheld welding machine has demonstrated outstanding performance in aluminum welding:

“Small Core Diameter” Laser Technology for Greater Penetration Depth

STRION LASER’s independently developed “small core diameter” laser technology increases laser output by 30% compared to conventional laser equipment. By enhancing energy output while reducing the heat-affected zone, this technology delivers higher precision welding for aluminum materials, achieving an exceptionally high depth-to-width ratio.

Real-time Wire Feeder Synchronization with Intelligent Wire Break Control

Considering aluminum’s high reflectivity and strong thermal conductivity, a new balance must be struck between laser power and welding speed during operation. Therefore, when designing the real-time wire feeder synchronization for the STR-HW Series, a wire retraction buffer is implemented after releasing the trigger. Additionally, power ramp-down parameters are optimized to prevent excessive molten pool depth at the weld termination, thereby avoiding welding defects.

Process Parameter Matching for Optimal Results

The process parameter packages, validated through tens of thousands of tests by our R&D team under standard operating conditions, offer a “one-touch welding” experience for customers with typical requirements. For clients with higher demands, we provide diversified and customized process package services tailored to their specific needs.

Handheld laser welders make aluminum welding simpler and more efficient. Widely used across various metalworking applications, they provide more reliable support for the development of industries worldwide.

Customer Insights: Top Mistakes in Aluminum Handheld Laser Welding and How to Fix Them

After consolidating feedback from multiple customers who have also used handheld welders from other brands, we found that aluminum sheet welding requirements vary significantly across manufacturers. When adjusting process parameters, multiple trials and fine-tuning must be conducted based on the specific application scenarios of the aluminum material to achieve optimal welding results.

Misconception 1: Using Handheld Welding to Stack and Fill Weld Seams

Welders accustomed to using MIG welding often rely on stacking filler wire to fill weld seams. However, this approach in aluminum processing can significantly increase both material and labor costs. Due to the high energy density of laser welding, repeatedly welding the same spot can easily cause burn-through, resulting in unsatisfactory weld quality. Instead, increasing laser power or adjusting the oscillation width, combined with multiple test welds, is recommended to achieve optimal results tailored to the specific welding environment.

Misconception 2: Performing Multiple Welding Passes Along the Same Seam

Some welders who do not fully understand the principles of laser welding or lack precise control over laser power mistakenly believe that handheld laser welding produces minimal spatter and heat, and cannot fully penetrate the material. As a result, they perform multiple welding passes along the same seam. In aluminum processing, due to aluminum’s strong oxidation tendency, this practice often leads to porosity in the weld seam. If a second pass on the same spot is necessary despite optimized process parameters, it is recommended to allow the workpiece to cool, grind the area, and then proceed with the welding operation.

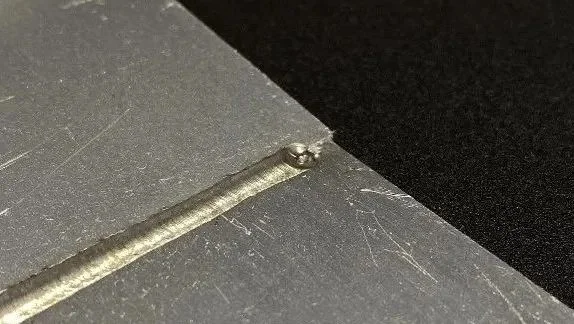

Misconception 3: Applying Excessive Force When Ending the Weld, Causing a Pit at the Weld Tail

Aluminum’s high thermal conductivity and relatively soft texture compared to other metals mean that laser dwell time at the same spot should be minimized. Due to the characteristics of laser welding, when the welding speed decreases before the laser shuts off, and the laser power-off does not synchronize instantaneously with the wire feeding speed, a deeper molten pool may form at the end of the weld seam. Novice welders encountering this issue can use a secondary tack weld in the opposite direction to fill the weld tail.

With a deep understanding of the market and customer needs, STRION LASER is committed to customizing welding parameters such as laser power and oscillation width based on the specific welding environment, sheet thickness, and material type to ensure optimal welding results. We also encourage customers to explore the full adaptability of the STR-HW Series handheld welding process packages through hands-on use, enabling rapid development of customized process packages tailored to their specific work scenarios.