Does Handheld Laser Welding Require Skilled Operators?

In today’s highly competitive manufacturing environment, small and medium-sized workshops often face a dual challenge: upgrading welding technology to improve efficiency and quality, while struggling to recruit and retain experienced welders. This has led many buyers to ask an important question: does handheld laser welding, as an advanced manufacturing tool, require highly skilled and experienced operators?

As a professional brand dedicated to laser welding technology, STRION LASER has long focused on reducing the operational barrier of advanced equipment through practical engineering and system optimization. Based on the design concepts and real-world application feedback of the MASTER X Series and LITE S Series handheld laser welders, this article examines the actual skill requirements of handheld laser welding and explains how intelligent machine design enables operators with different experience levels to achieve stable, efficient, and repeatable welding results.

The Skill Gap: Why Traditional Welding Demands “Master-Level” Operators

To understand the skill requirements of handheld laser welding, it is important to first look at why traditional welding methods—such as TIG welding and gas-shielded arc welding—place such high demands on operators.

- Parameter control relies heavily on experience:Traditional welding requires operators to manually adjust current, voltage, welding speed, and wire feeding rate based on personal judgment. Even small deviations can lead to uneven weld beads, insufficient penetration, excessive spatter, or weak joints.

- Operational stability is critical:Torch angle, hand stability, travel speed, and the distance between the torch and the workpiece directly affect weld quality. Achieving consistent results typically requires years of hands-on practice to develop the necessary control and “feel.”

- Material adaptability comes from long-term experience:Different materials—such as stainless steel, aluminum alloys, and carbon steel—react differently to heat input. Welding varying thicknesses further increases complexity. Skilled welders must accumulate extensive experience to handle these variables while maintaining consistent quality.

This high skill threshold significantly increases labor costs, limits production scalability, and makes quality consistency difficult to maintain. For many small and medium-sized manufacturers, it has become a major bottleneck in improving efficiency and competitiveness.

Technology Innovation: How STRION LASER Lowers the Skill Barrier

As an upgraded alternative to traditional welding, handheld laser welding naturally reduces operating difficulty. STRION LASER further strengthens this advantage through targeted technological design, making high-quality welding accessible even to less experienced operators.

1. Built-in Process Programs: “One-Click Welding” Without Experience

For inexperienced operators, parameter setup is often the biggest challenge. STRION LASER handheld laser welders—both the MASTER X Series and LITE S Series—are equipped with 20+ pre-configured welding programs, calibrated for common materials such as stainless steel, carbon steel, aluminum, and galvanized sheet, across different thickness ranges.

For example, when welding 3mm stainless steel, the operator simply selects the corresponding program on the control panel. The system automatically matches optimal laser power, welding speed, focal offset, and wire feeding speed. This “one-click” operation removes the need to memorize complex parameter combinations. With basic training—typically 1–2 days—new operators can achieve consistent, qualified welds, significantly reducing reliance on highly skilled welders.

2. Ergonomic Design: Improving Operational Stability

Welding torch stability is another critical factor that directly affects weld quality. STRION LASER’s self-developed K-Series welding torch weighs only 390g and features an ergonomic grip designed to fit the natural shape of the hand, significantly reducing fatigue during long working hours. In addition, the integrated collimation module eliminates the need for traditional QBH alignment. Even with slight hand movement, the laser output remains stable, helping operators maintain consistent weld quality.

The torch is also equipped with a wire-feeding hook and a quick-mount structure, ensuring precise installation without deviation or loosening. Optional 5m or 10m integrated armored cables provide ample working range, allowing operators to easily adjust welding angles and positions. Compared with traditional welding methods, this design greatly reduces the difficulty of maintaining a stable distance between the torch and the workpiece.

3. Stable Performance: Compensating for Operator Variations

Even with intelligent features, minor operational inconsistencies may still occur, especially with less experienced operators. STRION LASER equipment is engineered with high-performance core components that effectively compensate for these variations and ensure consistent welding results:

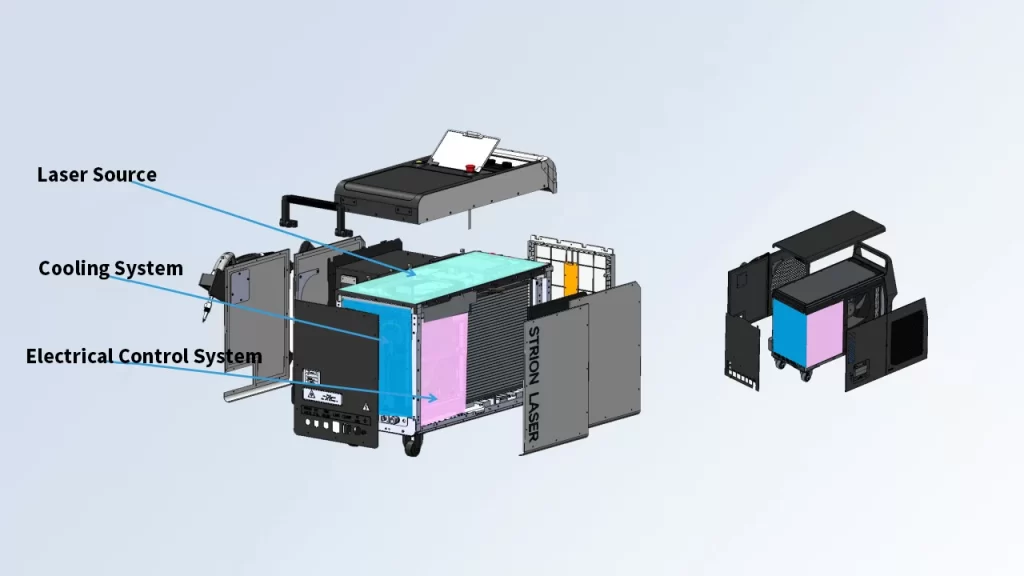

- Stable laser output: Annual power attenuation is less than 1%, with long-term power fluctuation also below 1%. This ensures consistent energy delivery over extended operating periods, preventing weld quality issues caused by unstable output.

- Dual-circuit refrigerant direct cooling system: The system supports continuous operation in temperatures ranging from -30°C to 60°C without overheating. Even if welding rhythm varies, the equipment maintains stable performance and consistent weld quality.

- High beam quality: The high-power fiber laser delivers excellent beam quality and strong penetration, making it well-suited for high-reflective materials such as aluminum. Compared to traditional welding, the system is less sensitive to torch-to-workpiece distance, offering greater tolerance and further reducing operating difficulty.

4. Intuitive User Interface: Shortening the Learning Curve

STRION LASER designs its control interface around the habits of everyday operators. The system features a clear, icon-based layout and a responsive touchscreen, making operation as intuitive as using a smartphone. Without specialized technical knowledge, operators can quickly learn to switch welding modes (spot welding / continuous welding), adjust wire feeding speed (25–150 cm/min), and start or stop the laser with confidence.

For companies with high staff turnover, this intuitive interface significantly reduces training time for new employees. It minimizes the impact of personnel changes on production and helps maintain stable, uninterrupted manufacturing output.

What Skills Do Operators Actually Need?

It is important to clarify that “lowering the skill barrier” does not mean “no skills required at all.” Even with intelligent handheld laser welding equipment, operators still need to master a few basic, easy-to-learn skills—all of which can be acquired in a short time:

- Basic workpiece preparation:Operators should understand how to remove oil, rust, and oxide layers from the workpiece surface using simple methods such as wiping with acetone or brushing with a wire brush. They should also know how to control the joint gap within 0.3 mm. These preparation skills are straightforward and can usually be learned within 1–2 hours of training.

- Basic equipment operation: Operators need to be familiar with fundamental functions such as switching the machine on and off, selecting the correct process preset, replacing welding wire, and performing simple torch cleaning (for example, wiping the protective window). STRION LASER provides detailed user manuals and video tutorials, allowing operators to learn independently without relying on extensive hands-on instruction.

- Essential safety awareness: All operators must understand basic safety requirements, including the correct use of personal protective equipment (laser safety glasses, flame-resistant clothing, gloves) and how to respond to abnormal situations, such as activating the emergency stop button. This is standard safety training and does not require prior welding expertise.

Together, these basic skills ensure that operators can work safely and effectively while fully benefiting from the efficiency and consistency of handheld laser welding technology.

Conclusion: The Future of Welding Lies in “Intelligence” Rather Than “Experience”

The answer to the question “Does handheld laser welding require skilled operators?” is: With the support of intelligent technology, handheld laser welding no longer relies on highly skilled operators. STRION LASER’s MASTER X and LITE S series handheld laser welders, through built-in process packages, ergonomic design, stable core performance, and intuitive operation interfaces, have significantly lowered the skill threshold for operation. Ordinary employees can achieve high-quality and efficient welding after simple training.

This not only solves the pain points of enterprises such as “difficulty in recruiting skilled welders” and “high labor costs” but also improves production efficiency and quality stability, providing strong support for the transformation and upgrading of small and medium-sized manufacturing enterprises.

If you are worried about the high skill threshold of handheld laser welding, or want to know how to quickly train operators to use the equipment, you can visit STRION LASER’s official website www.strlaser-en.com or call the consultation hotline +86-28 85812068. Our professional technical team will provide you with targeted solutions and training guidance, helping your enterprise quickly embrace the intelligent welding era.