This document compares the welding speeds achievable with Laser Welding and Tungsten Inert Gas (TIG) welding, highlighting the significant advantages of laser technology. Key factors influencing laser weld quality, particularly related to wire feeding and friction, are also discussed.

The speed of TIG welding

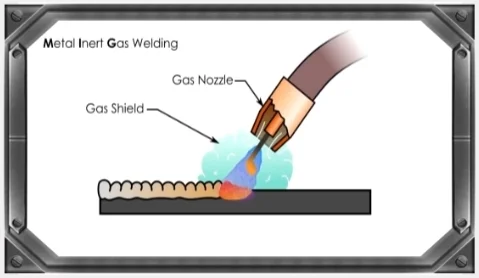

TIG welding is divided into manual tungsten TIG welding (TIG) and MIG welding, and the speed is affected by the operation mode, material thickness, and weld form.

Manual TIG welding:

TIG welding is divided into manual tungsten TIG welding (TIG) and MIG welding, and the speed is affected by the operation mode, material thickness, and weld form.

Sheet Welding (0.5 – 3 mm): Typical speeds range from 50 – 300 mm/min (e.g., ~100-200 mm/min for stainless steel thin-walled pipes).

Thick Plate Welding (5 – 10 mm): Speeds can be as low as 30 – 100 mm/min due to the requirement for multi-pass welding.

Key Limiting Factors:high arc stability requirements, too fast speed is easy to lead to non-fusion, porosity; When working manually, the welder’s physical strength and precision also limit the speed.

The speed of LASER welding

Laser welding (taking fiber laser as an example) has concentrated energy, small heat input, and significant speed advantages, which will appear perfect welding beam.

Sheet Welding (0.1 – 3 mm):

Typical Speed Range: 1000 – 5000 mm/min (1 – 5 m/min).

Examples:

Welding 0.3 mm stainless steel foil can exceed 8000 mm/min.

Automotive thin-walled components (e.g., door frames) are typically welded at 2000 – 4000 mm/min.

Plate Welding (3 – 10 mm):

Utilizing high-power lasers (e.g., > 6000 W), speeds remain significantly higher than TIG welding at comparable thicknesses.

Typical Speed Range: 500 – 2000 mm/min.

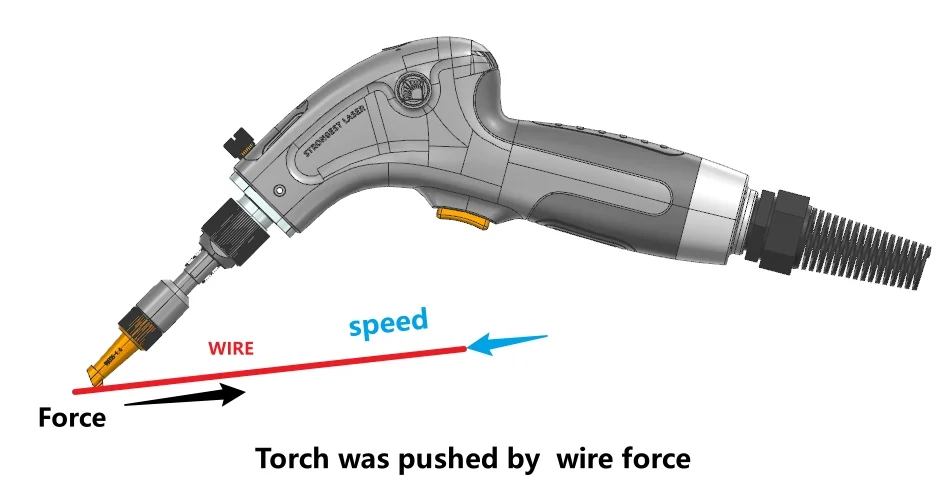

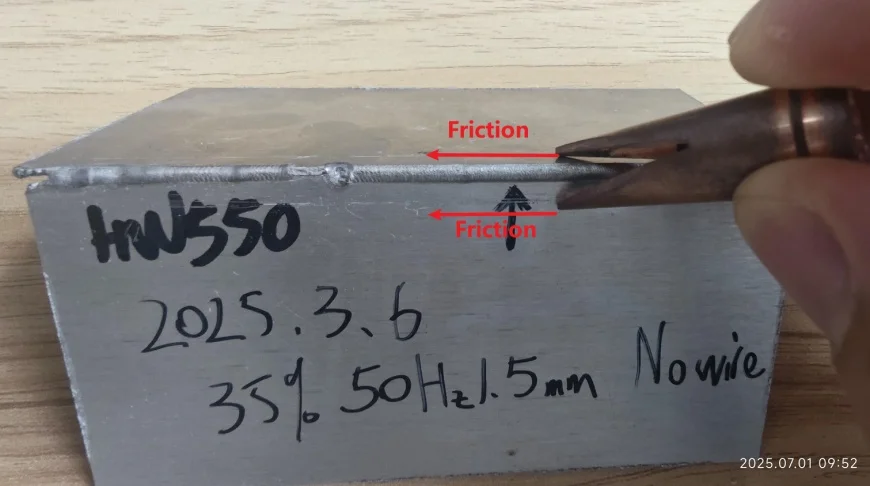

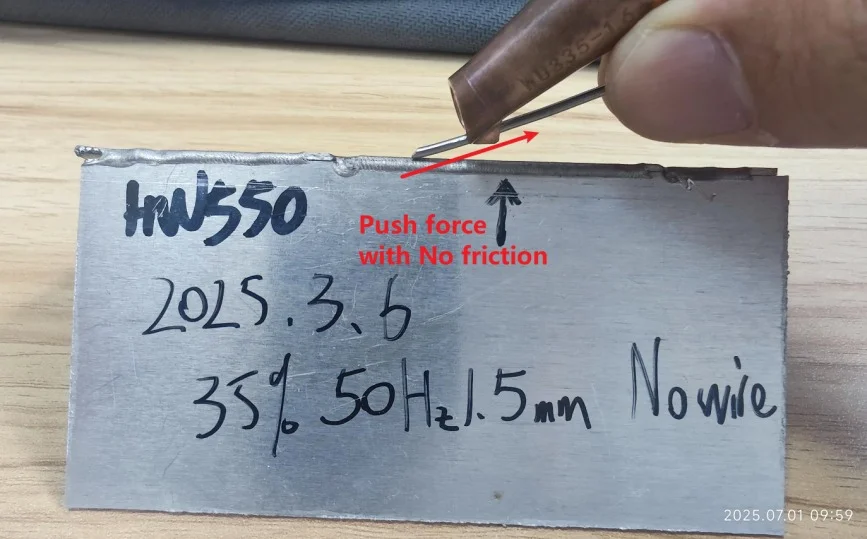

The friction and force of LASER welding

Wire feeding speed and friction between nozzle and workpiece will influence the beam surface, stable wire feeding speed will optimize weld uniformity. For better look, LASER welding perform better.(control wire feeding speed and choose less friction nozzle).

No wire feeding welding

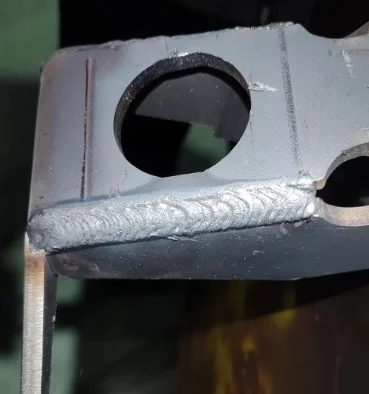

Wire feeding welding

Laser welding offers significant speed advantages over TIG across material thicknesses due to its high energy density and low heat input.At STRION LASER, we advance laser welding technology to deliver superior weld quality and production efficiency. Through innovation, we provide solutions that enhance welding speed and quality.