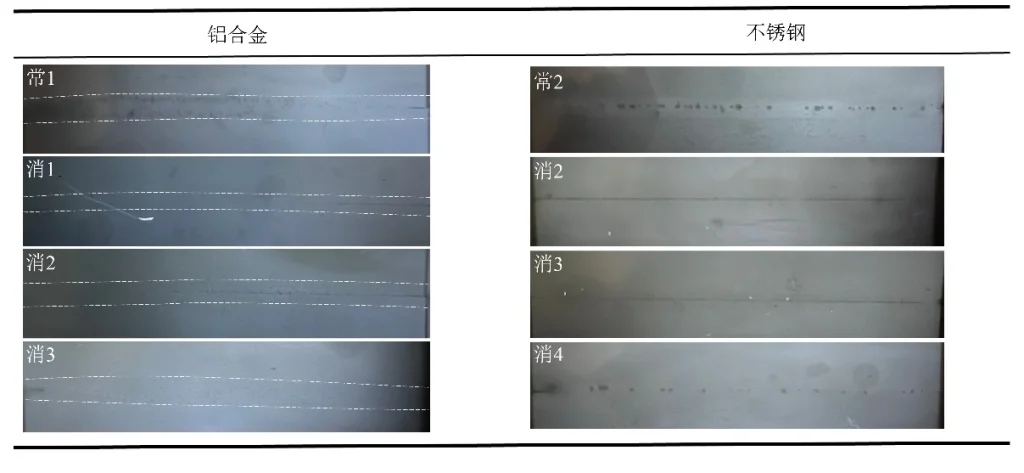

1. Porosity

Causes:

Excessive welding speed: A fast speed shortens molten pool duration, trapping gas bubbles.

Surface contaminants: Oil, moisture, or rust on stainless steel decompose into gas during welding, forming pores.

Solutions:

✔ Reduce welding speed to allow gas escape.

✔ Clean surfaces thoroughly (use acetone or alcohol).

2. Cracks

Causes:

Welding stress: Rapid heating/cooling generates stress exceeding the material’s yield strength.

Poor material composition: High carbon content or unbalanced alloys reduce crack resistance.

Overly fast cooling: Forms brittle martensite, increasing crack risk.

Solutions:

✔ Pre-heat materials to slow cooling rates.

✔ Optimize alloy composition (e.g., control carbon content).

3. Sparks & Spatter

Causes:

Excessive laser energy: Overmelting causes violent metal vaporization.

Incorrect focus position: Uneven energy distribution destabilizes the molten pool.

Slow welding speed: Overheating increases metal fluidity, triggering sparks.

Solutions:

✔ Calibrate laser power to match material thickness.

✔ Adjust focus position for even energy density.

✔ Increase welding speed moderately.