In recent years, handheld laser cleaning machines have emerged as one of the most advanced and efficient tools for industrial and precision surface cleaning. With the ability to remove contaminants, coatings, rust, or residues without damaging the substrate, this technology is gaining traction across manufacturing, restoration, automotive, and aerospace industries.

But one of the most common questions asked by potential users is: What materials can actually be cleaned using a handheld laser cleaning machine? The answer depends on both the type of material and the type of contaminant being removed. This article explores compatible materials, cleaning applications, and real-world use cases for laser cleaning systems.

How Handheld Laser Cleaning Works

Handheld laser cleaning machines utilize high-powered laser beams to remove unwanted materials from surfaces through a process known as laser ablation. Unlike mechanical or chemical cleaning methods, laser cleaning is a non-contact, non-abrasive, and environmentally friendly process. It selectively targets contaminants like rust, paint, or oxidation without harming the underlying base material.

Several factors influence how effectively a laser can clean a given surface, including:

- Laser power and pulse duration

- Wavelength and beam size

- Material reflectivity and thermal properties

By adjusting these parameters, handheld laser systems can be customized for a wide variety of materials and cleaning tasks.

Metals That Can Be Cleaned

1. Steel (Carbon and Stainless Steel)

Steel is one of the most common and ideal materials for laser cleaning. Handheld laser machines can efficiently remove:

- Rust and corrosion

- Oil and grease residues

- Paint and coatings

- Welding oxides

The process is especially valuable in welding preparation and post-welding clean-up for stainless steel fabrication, without grinding or using chemicals.

2. Aluminum and Aluminum Alloys

Aluminum is widely used in aerospace, automotive, and electronics. While it’s a soft and reflective metal, laser cleaning (with proper tuning) can remove:

- Anodized coatings

- Oxidation layers

- Grease and surface contamination

Care must be taken to avoid overexposure due to aluminum’s high reflectivity, but the results are highly effective when managed correctly.

3. Copper and Brass

Copper and brass are delicate and conductive metals used in electronics and precision components. Handheld laser machines can be used for:

- Cleaning oxidation without scratching

- Removing thermal stains post-soldering

- Prepping surfaces for joining

These metals require precise control over pulse energy and scanning speed, which most modern handheld lasers can handle.

4. Titanium

Titanium is favored in high-performance applications due to its strength-to-weight ratio and corrosion resistance. Laser cleaning is ideal for:

- Surface prep before coating or bonding

- Oxide layer removal

- Fine cleaning in aerospace and medical equipment manufacturing

Because titanium is heat-resistant, it tolerates laser exposure well without deformation.

Non-Metallic Materials That Can Be Cleaned

While metals are the primary targets for laser cleaning, non-metallic materials can also be cleaned with proper power adjustment.

1. Stone and Concrete

Laser cleaning is highly effective in cultural heritage conservation, removing:

- Graffiti

- Pollution deposits

- Biological growth like moss or lichen

It allows restoration of delicate stone carvings and monuments without using harsh abrasives or water.

2. Rubber and Plastics (Selectively)

Mold tools used for rubber and plastic parts accumulate buildup from repeated use. Laser cleaning can:

- Remove residue without damaging mold detail

- Clean release agents and carbonization

- Reduce downtime in injection molding facilities

However, direct laser application on plastic surfaces should be done cautiously, as some polymers can melt or deform under heat.

3. Glass and Ceramics

Laser cleaning can gently remove:

- Contaminants

- Coatings

- Fine residues

It’s useful in specialty glassware and electronics, although extreme care must be taken to avoid cracking due to rapid heating.

Coatings and Contaminants That Can Be Removed

Regardless of the base material, handheld laser machines are exceptionally capable of removing:

- Rust and corrosion

- Paint (powder, enamel, spray, graffiti)

- Oil, grease, and adhesives

- Oxidation and anodized layers

- Soot, carbon buildup, and residues from combustion

- Plating or coating layers (in precision operations)

This makes them extremely valuable in industrial maintenance and refurbishment operations.

Materials Not Suitable or Requiring Caution

While handheld laser cleaning is highly versatile, not all materials are ideal for this process:

- Thin plastics and rubber: Can melt or burn if not properly tested.

- Highly reflective metals (mirror-finish aluminum, gold): Can reflect laser beams, causing safety risks or reduced efficiency.

- Painted wood or textiles: Often flammable and easily damaged.

- Transparent materials (glass, certain resins): May not absorb laser energy efficiently, making cleaning less effective.

Proper testing and parameter adjustment are essential for these edge cases.

Common Industry Applications

1. Automotive Industry

- Cleaning of engine parts, molds, and dies

- Rust and paint removal

- Surface prep for welding or coating

2. Aerospace and Aviation

- Delicate surface decontamination

- Oxide removal from titanium and composites

- Pre-coating cleaning for bonding and adhesion

3. Heritage Restoration

- Graffiti removal

- Restoring historic monuments

- Cleaning delicate sculptures

4. General Manufacturing

- Tool and mold cleaning

- Production line maintenance

- Electrical and electronic surface preparation

Tips for Safe and Effective Laser Cleaning

To achieve optimal results and protect both the operator and the material:

- Test on a small area first to determine the best settings

- Use safety goggles and proper PPE to protect from laser exposure

- Maintain proper ventilation to remove fumes or particles

- Regularly inspect the laser optics and cooling system for maintenance

Training and professional guidance are recommended for new operators.

Conclusion

Handheld laser cleaning machines represent a major advancement in material surface preparation and maintenance. Their ability to precisely remove rust, paint, grease, and other contaminants from a wide range of metals and non-metal materials — without damaging the base material — makes them an indispensable tool in modern industry.

Whether you’re in aerospace, automotive, restoration, or electronics, laser cleaning offers a cleaner, faster, and more eco-friendly solution. However, understanding material compatibility is key to unlocking its full potential.

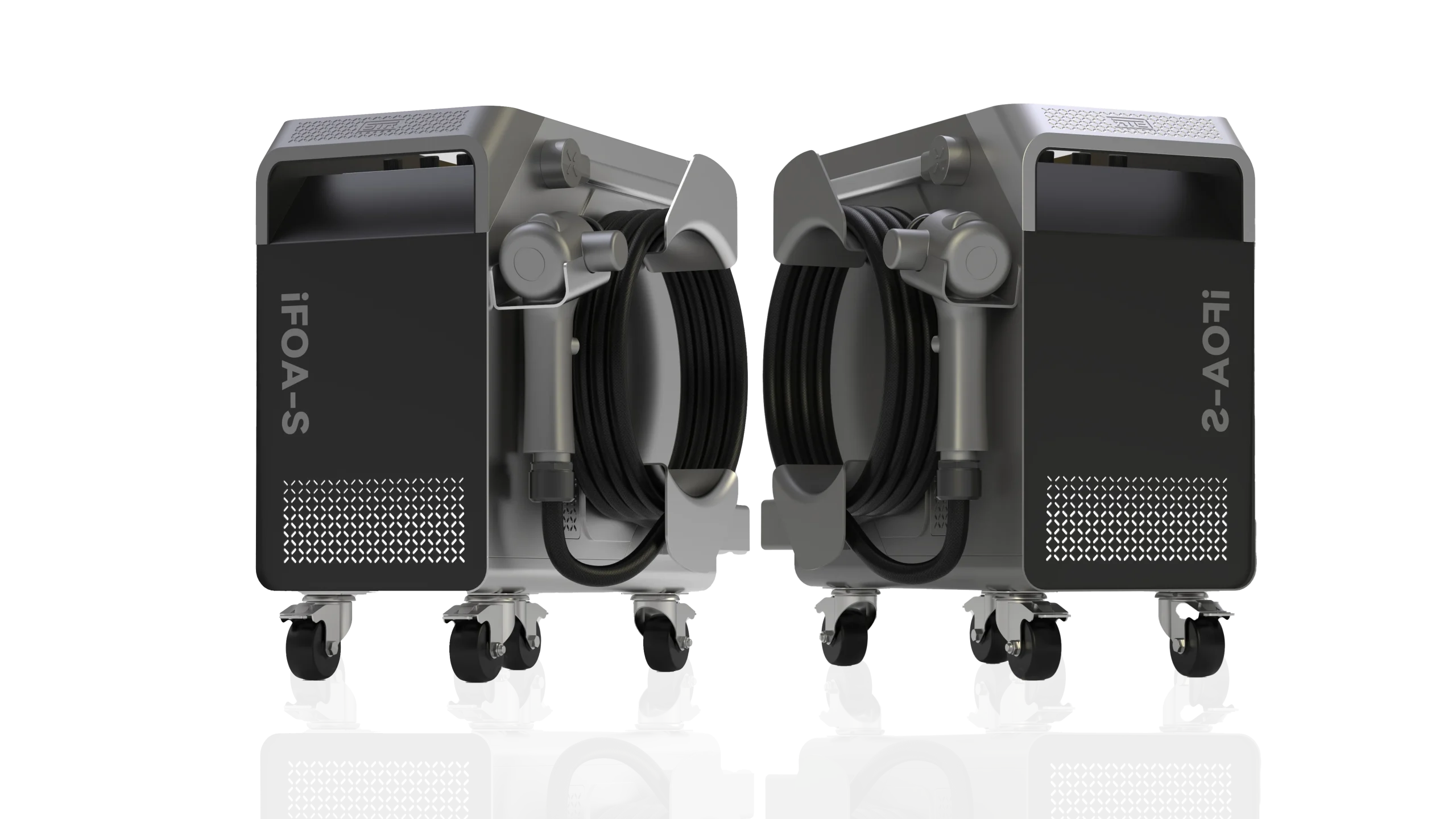

If you’re exploring the possibilities of handheld laser cleaning for your operation, consider consulting a trusted brand like STRION LASER, known for high-performance laser cleaning systems that deliver precision, safety, and efficiency across industries.