Public Release

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Public Release

while the initial purchase cost of laser welding equipment is higher, the overall cost-effectiveness of laser welding improves due to its higher efficiency and lower consumable costs over time.

Meanwhile, its user-friendly operation interface and excellent after-sales service have won customers' trust and love.

Avoid Porosity & Oxidation: A Data-Driven Guide to Laser Welding Gas Selection

To address the rapid consumption of protective windows in laser welding applications (especially with handheld laser welding machines), here are targeted solutions

The K20 Welding Gun embodies the perfect fusion of technological innovation and craftsmanship optimization, with revolutionary design breakthroughs that push the limits of performance. Choosing the K20 means choosing efficiency, reliability, and the future of welding.

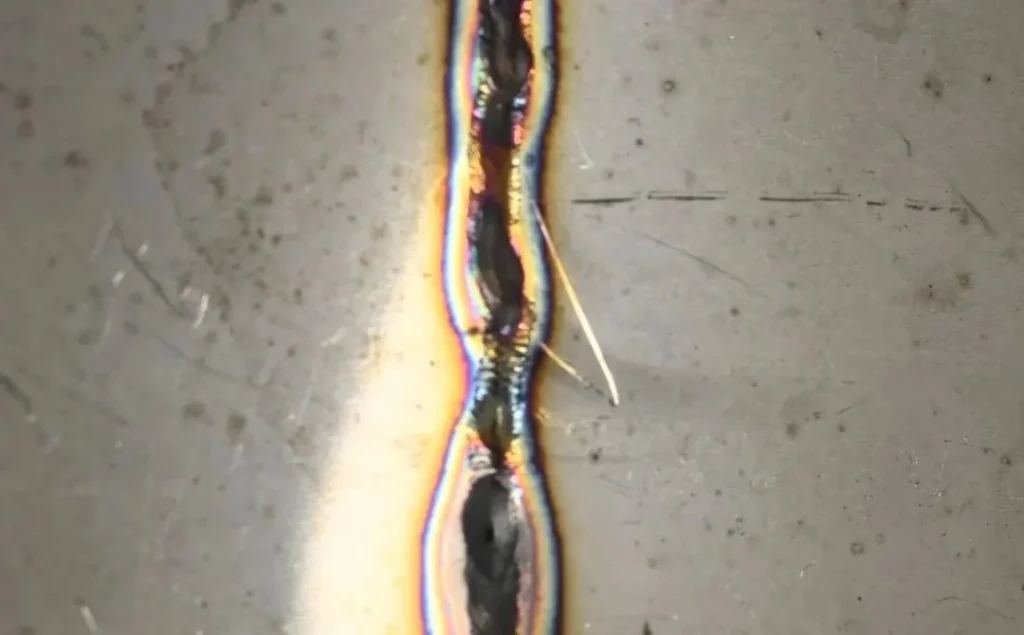

STR-HW series handheld welding machine, to achieve continuous mode of 0.5mm welding without worry, pulse mode breakthrough to 0.2mm welding process limit.

Government and Industry Collaborate to Advance Intelligent Manufacturing. Delegation from Sichuan Luzhou (Yangtze) Economic Development Zone Visits STRONGEST LASER for In-Depth Exchange

The STR-HW series handheld laser welder is widely adopted for its efficiency, stability, and convenience. Leading biopharmaceutical company BIO-YD uses it for high-precision medical tank welding, ensuring stringent sanitary standards.

A delegation from our South African distributor visited the STRONGEST LASER headquarters to gain an in-depth understanding of the company's core technologies and product lines. Both parties engaged in extensive discussions on various fields, including handheld laser welding, automated welding systems, and specialized welding technologies.

Automated welding technology, which refers to the use of robotic and computerized systems to perform welding tasks, has become increasingly important in modern production environments. This technology has not only improved the quality and consistency of welded joints but has also allowed manufacturers to streamline operations, reduce costs, and enhance worker safety.