Public Release

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Public Release

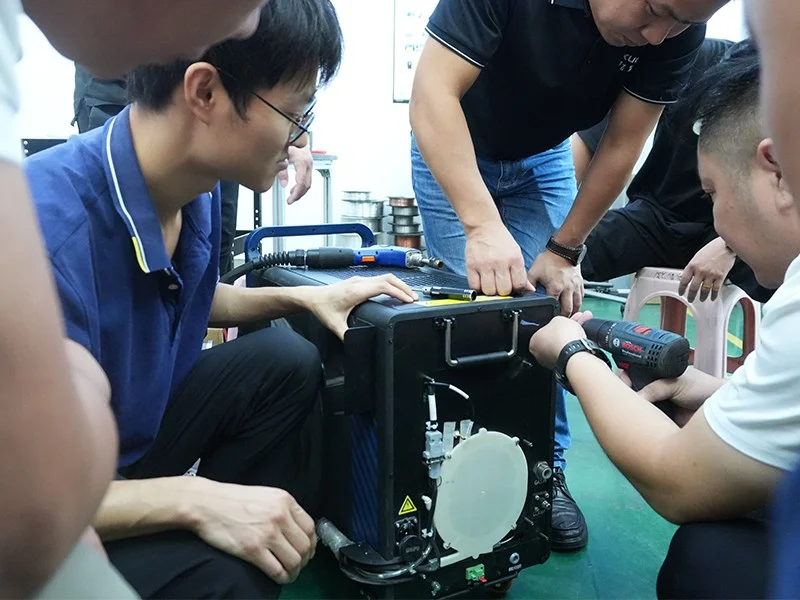

STRION LASER concluded a nationwide distributor training, boosting technical capabilities and deepening knowledge to enhance service and drive future growth.

Proven in the critical field of boiler membrane wall repair, STRION LASER handheld welding has demonstrated undeniable advantages: faster construction speed, minimal deformation, superior quality, and cost savings.

Recently, Zheng Yongpeng, Deputy Secretary of the Party Working Committee and Director of the Administrative Committee of Fuping High-Tech Industrial Development Zone in Shaanxi Province, along with his delegation, visited Sichuan strongest Laser Technology Co., Ltd. for a Party building study and exchange symposium.

The training was structured into two levels—Level 1: Foundation Training and Level 2: Advanced Training—covering everything from basic installation to advanced fiber maintenance and welding process optimization.

STRION LASER Drives Innovation in High-Power Continuous Fiber Lasers at the OVC EXPO

STRION LASER is pleased to unveil its upgraded brand logo, representing a refined visual identity that bridges ancient philosophy with modern technology — a natural evolution aligned with the company's growth in the laser welding industry.

As a leading enterprise in China’s high-power laser technology sector, STRION LASER (SSichuan Strongest Laser Technology Co.,Ltd.) was invited to attend the event.

STRONGEST LASER’s independently developed 10kW-class high quality laser beam fiber laser source achieved a major breakthrough in field testing—successfully demonstrating an effective neutralization range exceeding 3 kilometers.

STRONGEST LASER has actively driven the rapid advancement of domestic laser technology through continuous innovation and breakthroughs in high-power fiber laser technology.

Common defects in laser welding include porosity, cracks and sparks. This article will summarize their causes and solutions.