Public Release

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Public Release

Strion Laser has addressed two recurring user questions: achieving smooth arc pit control during weld termination and efficiently welding thick stainless steel plates with consistent penetration and quality.

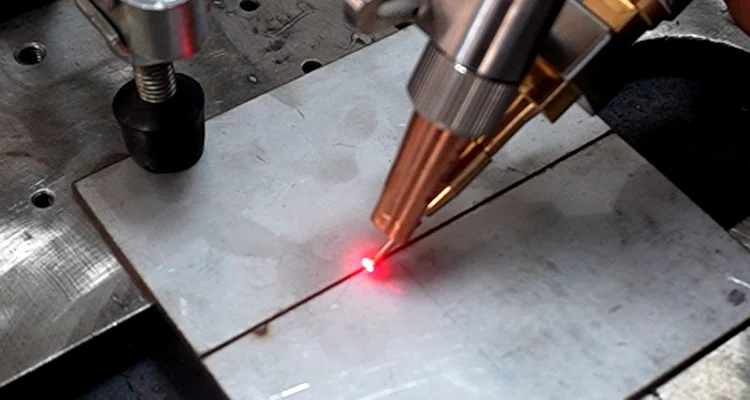

Recently, STRION LASER demonstrated its mastery in precision laser welding through a remarkable project: joining 0.5mm titanium alloy components to craft a teapot.

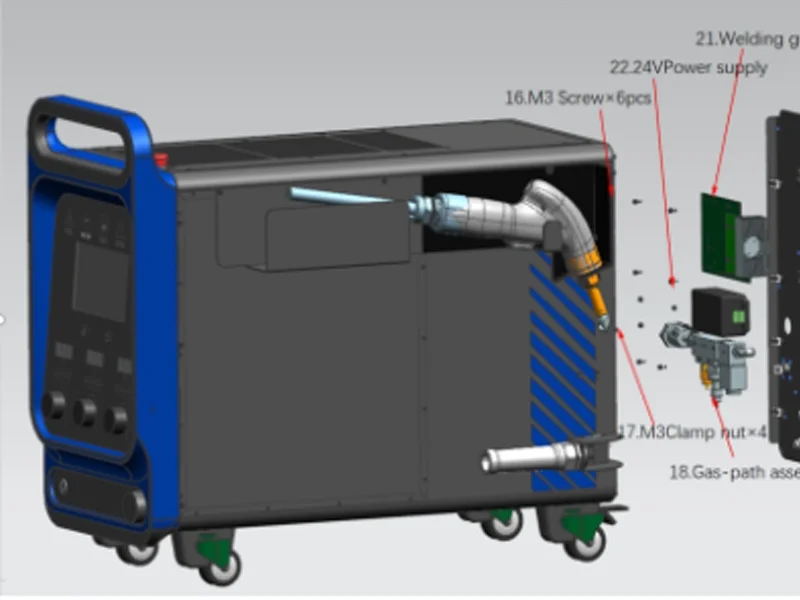

Here, we break down the core components, auxiliary systems, and key design features that define the structural design of a laser welding machine.

With cutting-edge laser technology, we forged an unbreakable “Shield of Laser” above the arenas, ensuring that every moment of the Games unfolded in safety and brilliance.

STRION LASER has stepped up with advanced laser welding technologies and refined process strategies tailored to titanium’s unique metallurgy.

Strion Laser has independently developed a new generation of anti-back-reflection lasers by overcoming key technical barriers.

At STRION LASER, we’ve cracked the code with our factory-original protective lenses, engineered with precision to break the cycle of high loss and short service life.

STRION LASER’s new 3000W air-cooled laser source meets rigorous demands with breakthrough technology.This next-gen solution sets a new standard for special application laser sources where performance, durability, and portability are critical.

Strion Laser recently completed a successful welding solution for a customer facing the challenge of joining ultra-thin 0.3mm stainless steel sheets.

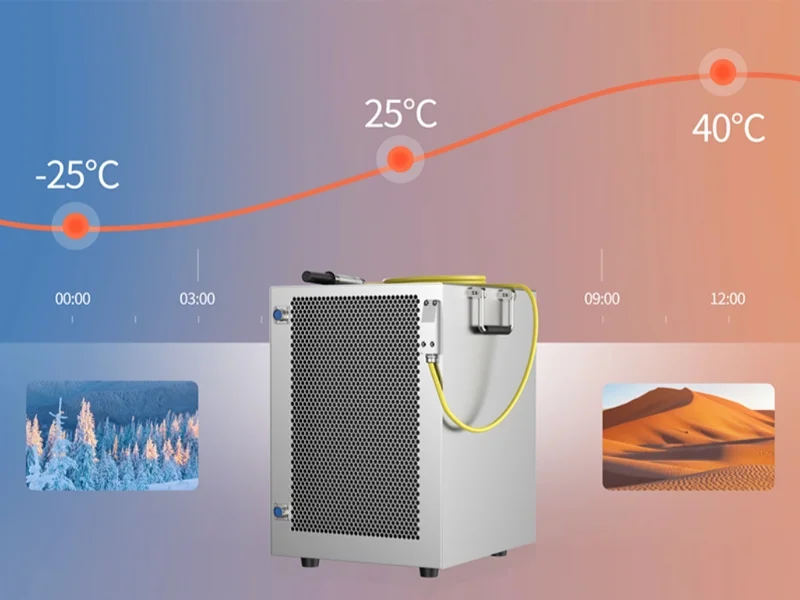

This article outlines how STRION LASER’s breakthrough technology ensures continuous and stable welding output in the face of extreme heat.