Public Release

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Public Release

STRION LASER LITE S Series embodies continuous technological innovation and rigorous manufacturing excellence — optimizing total cost of ownership while ensuring outstanding safety and reliability.

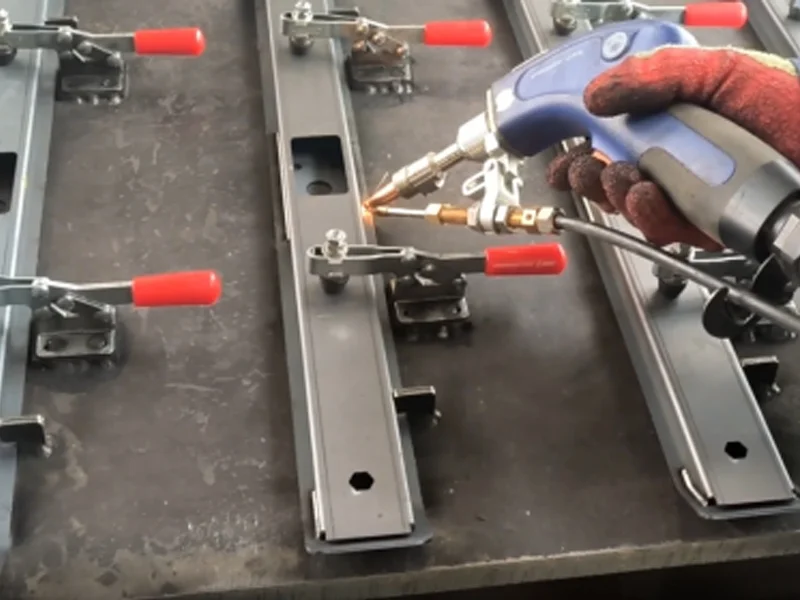

The LITES Series high-power, coolant-cooled handheld laser welders inherit STRION LASER’s core laser technology and, addressing key customer pain points, feature innovative design optimizations that significantly enhance reliability and ease of maintenance.

Strion Laser’s LITE S Series delivers a complete solution for welding thin plates up to 4mm, combining streamlined operation, enhanced efficiency, and intelligent upgrades.

As an important participant in the global laser industry, STRION LASER was invited to attend 2025 “China Welding Industry Forum – Conference on Robotic and Intelligent Welding Technologies and Applications”

STRION LASER welding solutions are designed to directly address these pain points, offering targeted solutions that help furniture manufacturers accelerate their shift toward intelligent, efficient, and high-quality production.

STRION LASER recently welcomed a delegation of entrepreneurs from diverse industries to its headquarters for an in-depth exchange and collaborative discussion. The visit aimed to strengthen mutual understanding, explore cross-industry opportunities, and drive innovation within the field of intelligent manufacturing.

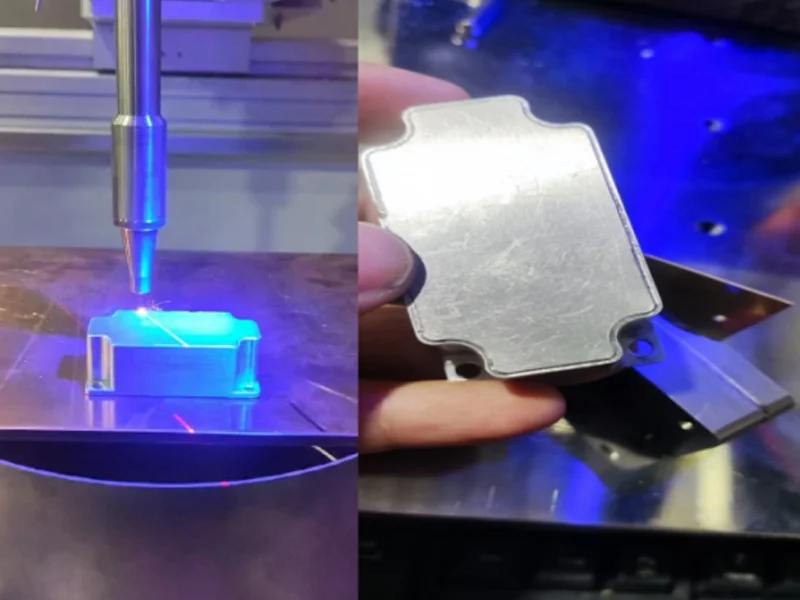

This article states that in the context of industrial demand for precise aluminum welding, STRION LASER’s AW550pro robotic welding system recently demonstrated its capabilities on aluminum boxes.

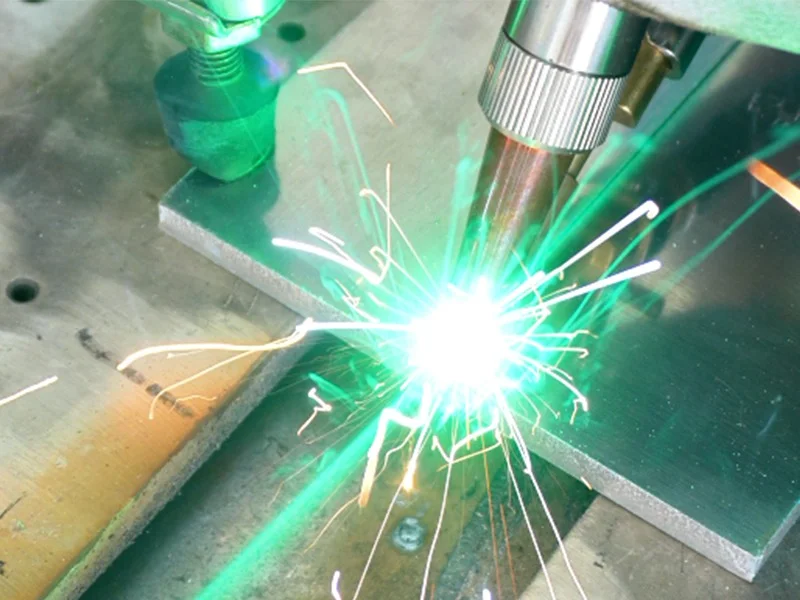

This case study will delve into how the MASTER X80 effortlessly tackles the challenges of welding high-reflectivity thick plates and why it stands out as the preferred choice for businesses in need.

In this guide, we cover key installation steps, including electrical signal setup, torch assembly, laser spot inspection, wire feeding, shielding gas management, and focal offset adjustment.

The STR-AW850 demonstrates superior performance in thin stainless steel welding, offering manufacturers a reliable solution for applications where clean, smooth, and spatter-free welds are essential.