Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

On the road of R&D and manufacturing of fibre lasers for additive manufacturing, SICHUAN STRONGEST LASER TECHNOLOGY CO., LTD (STR) deeply understands that "A journey of a thousand miles begins with a single step".

Due to the nature of laser technology, effectively managing laser energy emission and reception, as well as optimizing the cooling of supporting components, has become a critical challenge—especially in the development of compact and lightweight equipment.

Handheld laser welding machines have emerged as an innovative solution to many of the challenges faced by traditional welding methods. By addressing issues like thin material welding, poor weld aesthetics, high heat input, and slow speeds, laser welding has set a new standard in precision and efficiency.

Handheld laser welding machines offer a fast, efficient, and user-friendly alternative to traditional welding techniques. By following proper setup, operation, and maintenance procedures, operators can achieve high-quality welds with minimal distortion and post-processing.

In this article, we explore why handheld laser welding machines are gaining traction and how they can benefit metal fabrication processes.

Choosing between handheld laser welding machines and traditional welding methods depends on your specific needs. Handheld laser welders offer unmatched precision, portability, and speed, making them ideal for intricate tasks and thin materials. Traditional methods, however, excel in affordability and heavy-duty applications.

Fiber lasers excel in cutting metals with speed and precision, while CO2 lasers handle non-metals like wood and acrylic effectively.

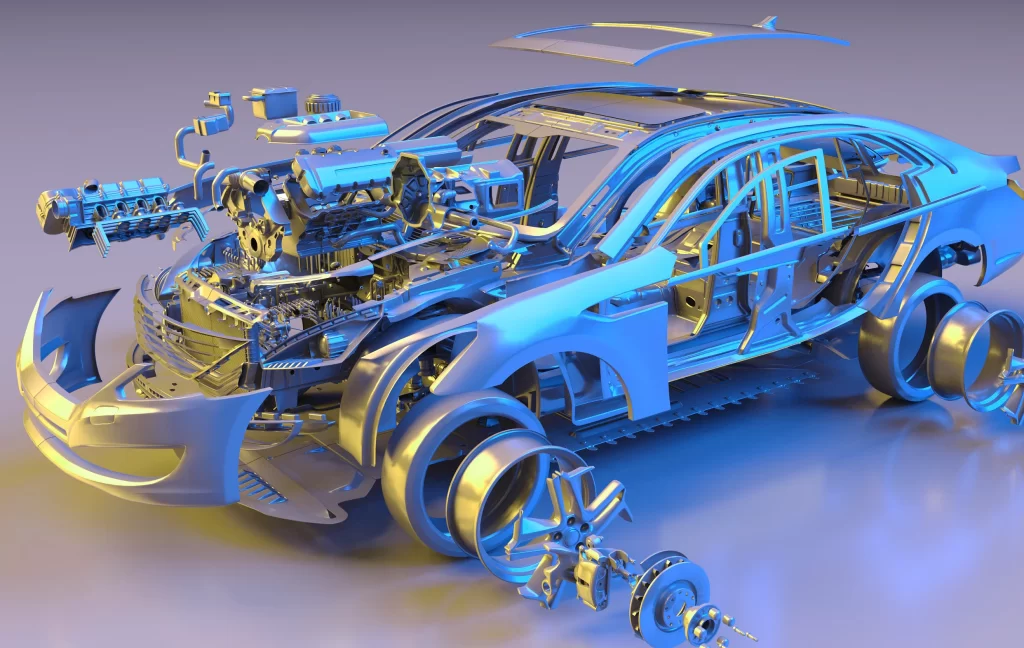

the application of STRONGEST LASER handheld laser welding machines in automotive manufacturing offers significant advantages, not only improving production efficiency and welding quality but also reducing production and time costs, while meeting the automotive industry's demands for high quality, precision, and reliability.

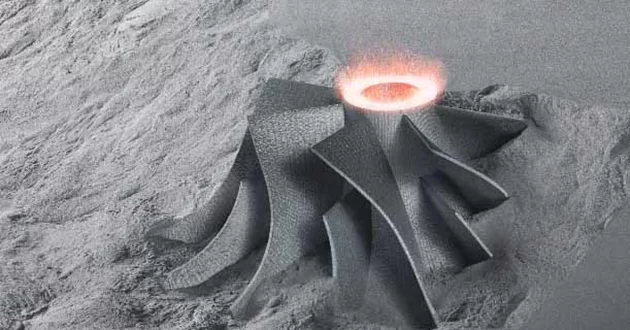

Laser 3D printing has become a game-changer in manufacturing. You can now create intricate designs with unmatched precision by building objects layer by layer. Businesses have embraced this technology rapidly.

In today's rapidly evolving technological landscape, laser technology has become an indispensable part of modern industrial manufacturing.