Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

Built for Durability—Inside and Out

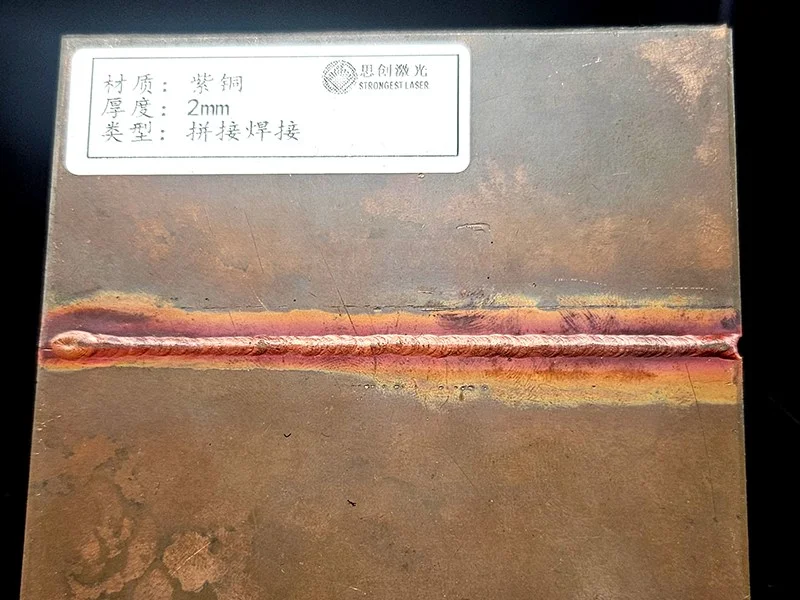

As manufacturing demands continue to grow, the use of handheld laser welding for copper has become a focal point in manufacturers’ promotions.

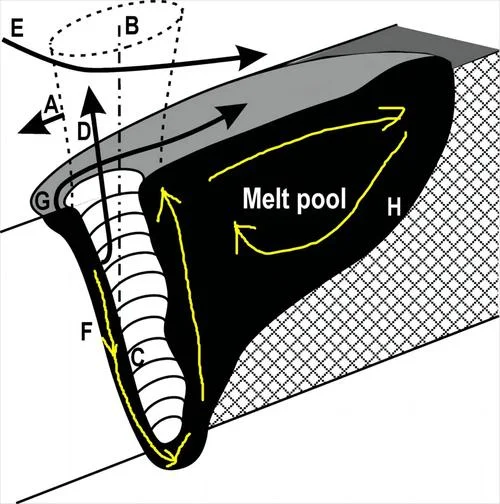

Weld pool instability in laser welding refers to the abnormal dynamic behavior of the weld pool (liquid metal area) during the welding process, which is manifested as keyhole oscillation, uncontrolled sparks, penetration depth fluctuation or irregular weld molding.

A refrigerant-cooled handheld laser welder with just 900W of power can now rival the welding performance of a 1500W assembled water-cooled model.

Common defects in laser welding include porosity, cracks and sparks. This article will summarize their causes and solutions.

In this article, we will compare fiber lasers and CO2 lasers, focusing on their working principles, advantages, and key differences, to help you make an informed decision.

As a leader in the industry, Strongest Laser specializes in the Additive Manufacturing Series Fiber Lasers, which are designed to enhance the performance and capabilities of 3D printing and other industrial applications.

Avoid Porosity & Oxidation: A Data-Driven Guide to Laser Welding Gas Selection