Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

In this article, we’ll share expert-recommended maintenance tips that will help extend the life of your handheld laser welder, reduce repair costs, and ensure optimal operation for years to come.

In an era of rapid industrial transformation, STRION LASER, a rising leader in China's advanced manufacturing sector, proudly launches its latest dual-line laser welding solutions: the MASTER X and LITE S series.

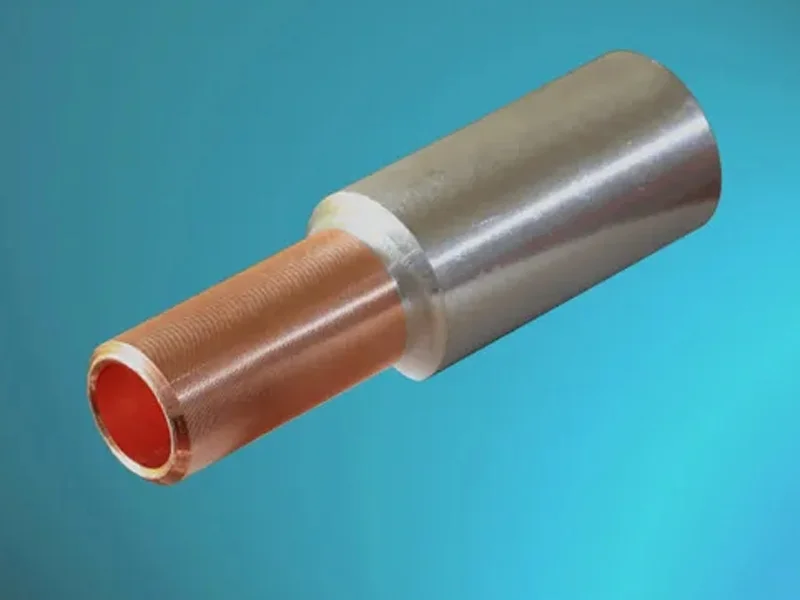

This article details STRION LASER’s solutions, backed by experimental data (Tables 1–2), and demonstrates their industrial applicability in achieving >30% stronger joints and near-parent-material conductivity.

STRION LASER has successfully completed a tensile and weld strength verification test on 430 stainless steel using its advanced 1.8M Sinomach robotic welding system (Model: HW850)

The combination of aluminum and laser welding seems like a perfect match at first glance. However, due to their conflicting characteristics, this pairing presents numerous challenges in practical welding operations.

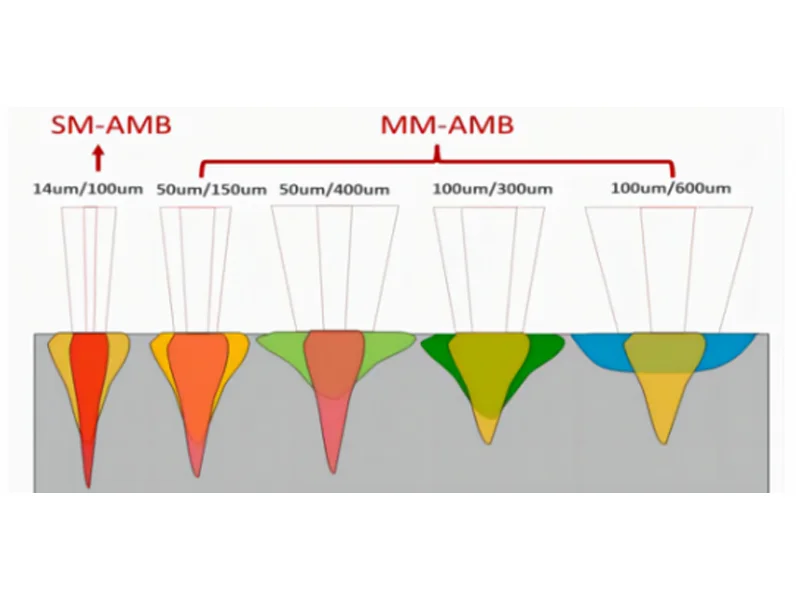

This article provides a detailed comparison of small-core and large-core fiber lasers, highlighting their respective strengths and ideal use cases.

BIO-YD has applied STRION LASER’s STR-HW Series handheld laser welding machine to the fabrication of high-standard sanitary-grade containers.

Some operators want to remove the interlock, but such welding operation is a very dangerous behavior - especially when using handheld laser welding machines or fiber laser welding systems.

Thermal effects dominate the cleaning mechanism. High power and large processing area adaptability. Balance between low cost and high efficiency

This article explores the key benefits of handheld laser welding machines and their growing significance in the fabrication industry.