Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

This article explores compatible materials, cleaning applications, and real-world use cases for laser cleaning systems.

This article provides key steps and considerations to ensure a successful aluminum alloy welding process, whether for manual, semi-automatic, or fully automated applications.

In this article,follow this procedure to ensure your torch operates efficiently and safely.

Our latest project features automated welding of carbon steel tube-sheet assemblies, delivering high-precision results with exceptional speed and quality.

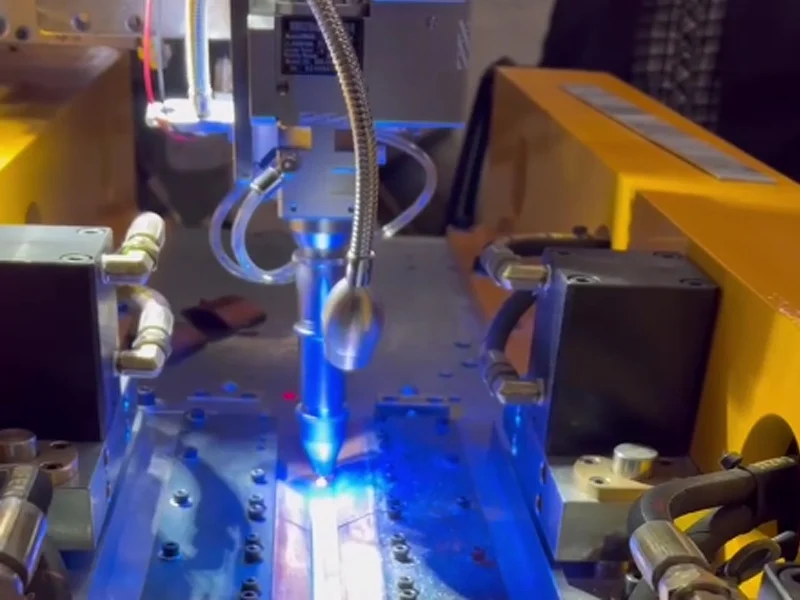

STRION LASER recently completed a successful application case of automated robotic laser welding for saddle-port thin tubes — a process requiring exceptional precision and thermal control.

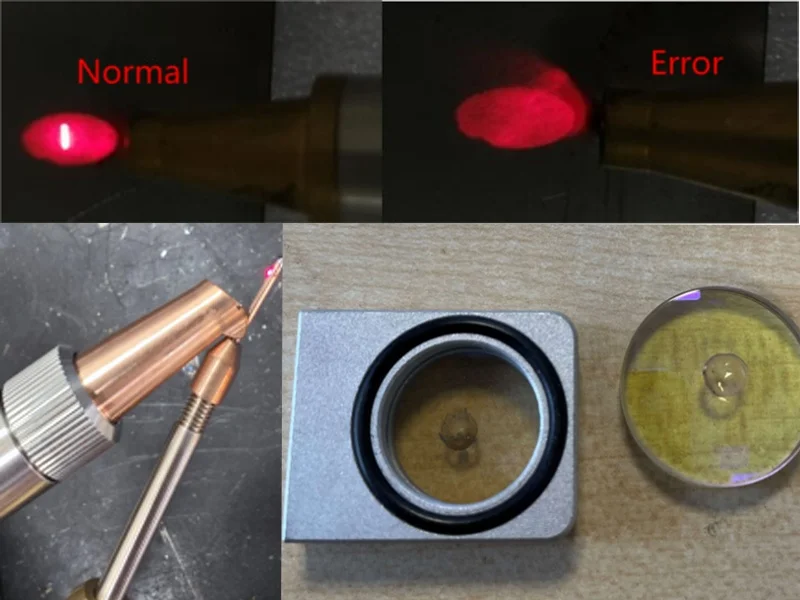

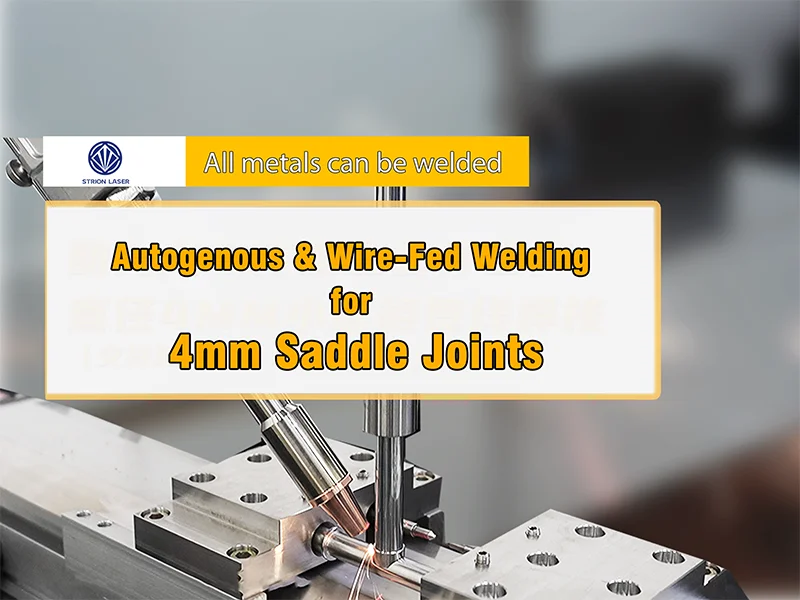

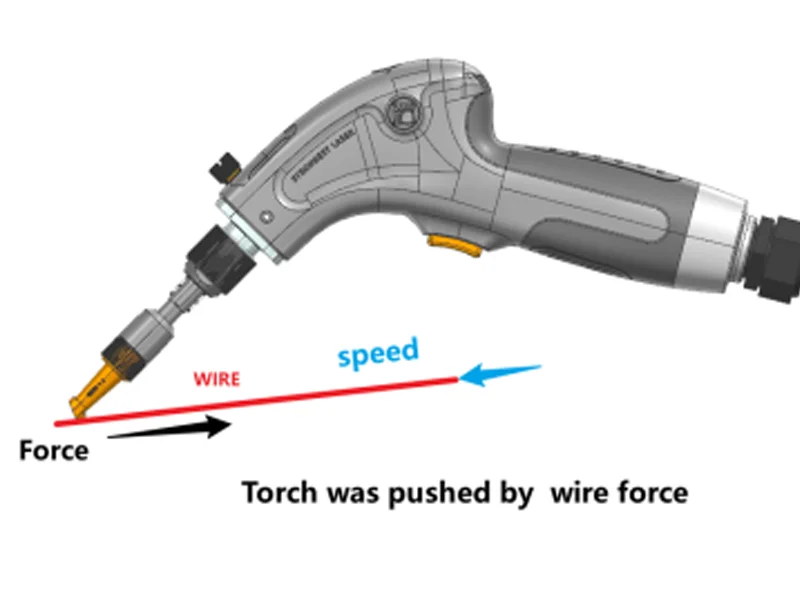

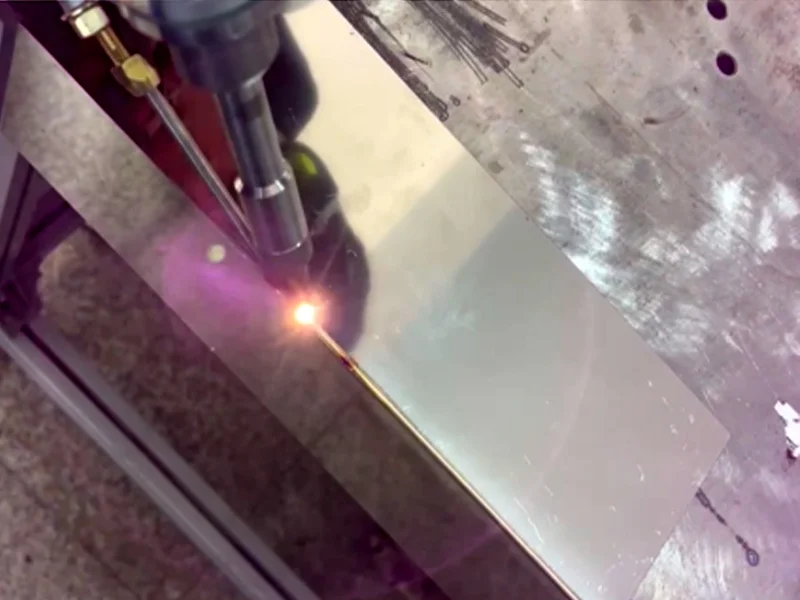

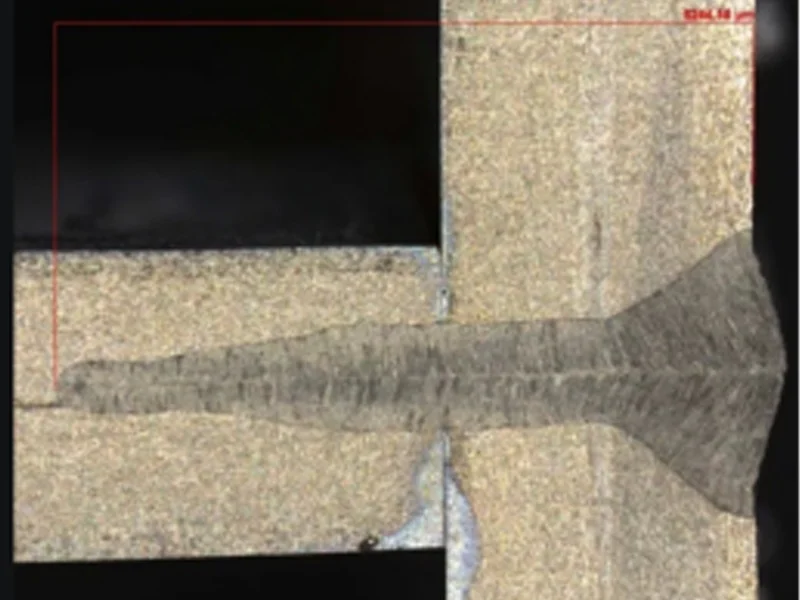

This document compares the welding speeds achievable with Laser Welding and Tungsten Inert Gas (TIG) welding, highlighting the significant advantages of laser technology. Key factors influencing laser weld quality, particularly related to wire feeding and friction, are also discussed.

STRION LASER’s handheld laser welding machine continues to prove its value in field applications, offering manufacturers a flexible, high-performance laser welding solution for a wide range of demanding tasks.

In this article, we’ll explore the types of metals best suited for handheld laser welding, why some materials are more challenging than others, and what factors affect overall weld quality.

STRION LASER is proud to share advanced strategies and best practices for high-quality copper (Cu) welding—particularly purple copper—drawing on extensive field experience and our latest equipment capabilities.

This article compares arc welding and laser welding in terms of welding morphology, oxidation behavior, and process selection logic—providing clear guidance for engineers and manufacturers.