Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

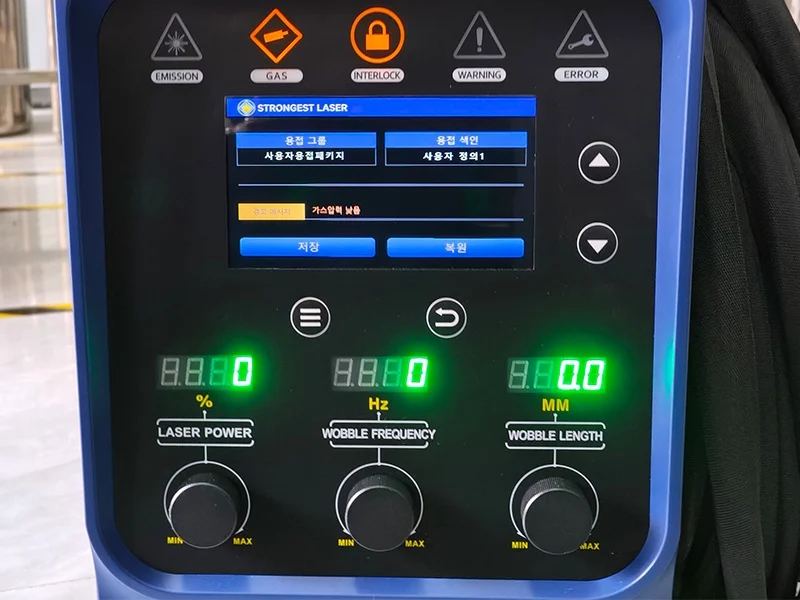

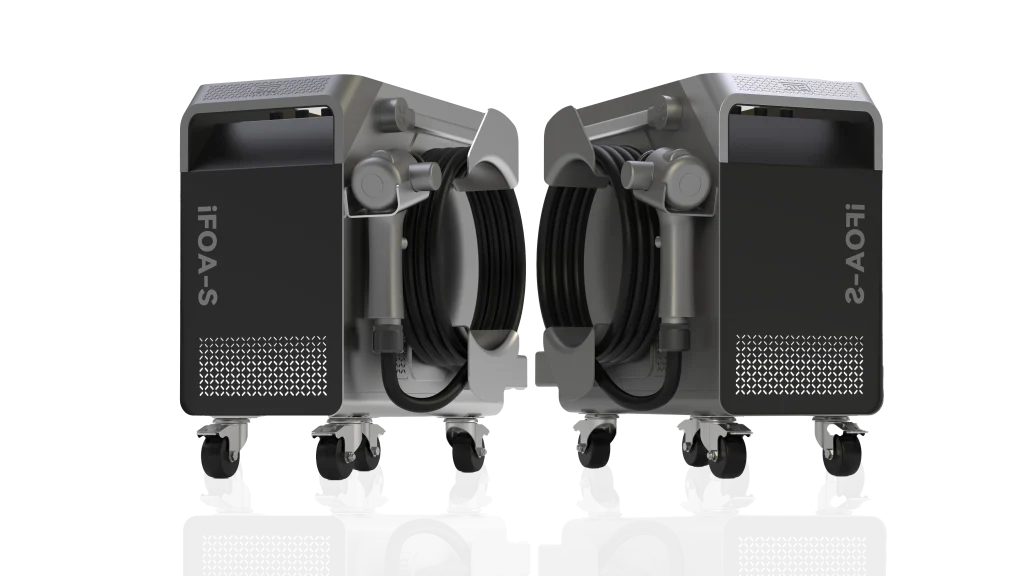

Learn the difference between air-cooled, water-cooled, and dual-circuit refrigerant direct cooling systems in handheld laser welders. Discover which cooling solution delivers the best performance, energy efficiency, and temperature stability for your laser welding machine.

This article highlights five key factors to consider before buying a handheld laser welder, helping you make a well-informed decision that balances performance, cost, and long-term value.

This article explores the unique challenges of thin plate welding, how handheld laser welders solve them, their key advantages, applications, best practices, and what the future holds.

Handheld laser welding is an efficient and high-quality welding method. However, since it involves the use of “lasers,” many people are concerned about whether it generates radiation or poses risks to the human body.

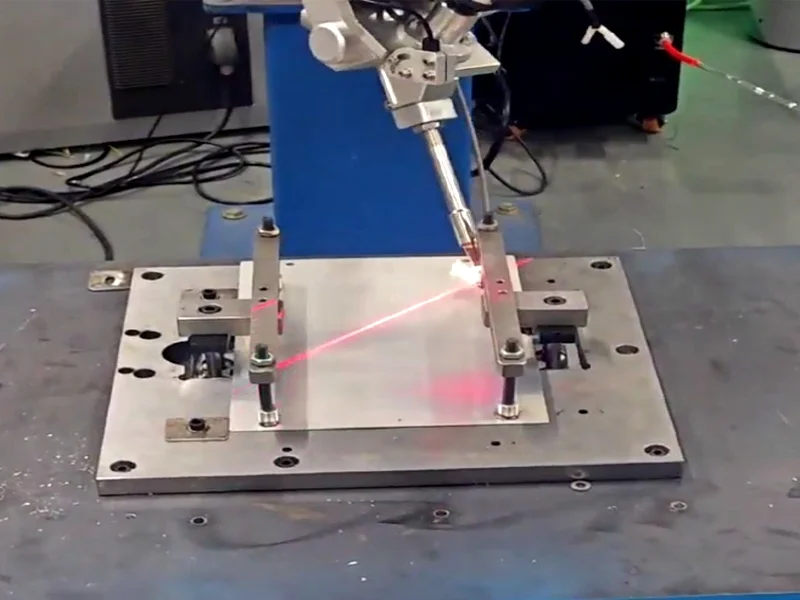

STRION LASER has conducted in-depth research on this laser welding process and shares key practices to help manufacturers improve weld quality while reducing rework rates.

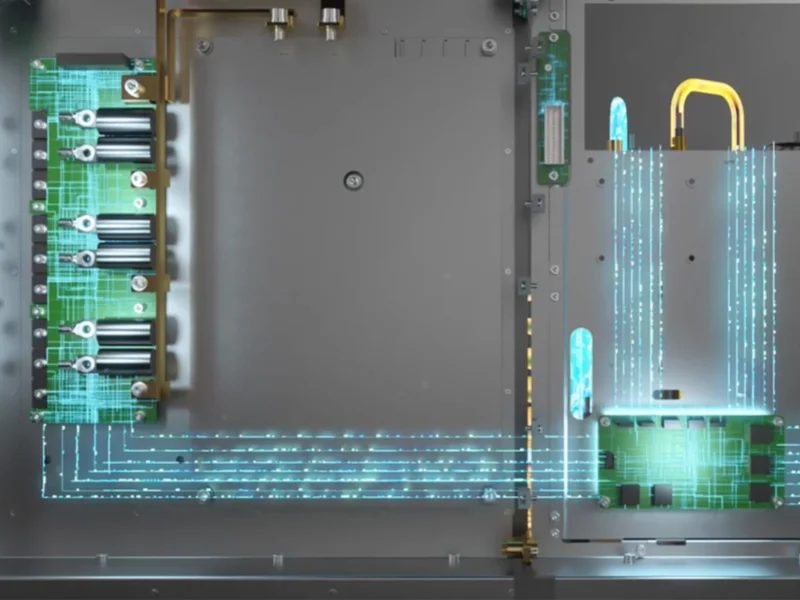

As intelligent manufacturing continues to evolve, STRION LASER stands at the forefront of innovation, providing seamless software-hardware integration and application-driven customization.

The applications of laser cleaning machines span a remarkable range of industries, from heavy-duty industrial processing to delicate cultural restoration.

Whether you’re evaluating a laser cleaning machine, considering dry ice blasting, or relying on sandblasting, this guide will help you identify the best solution for your needs.

STRION LASER is committed to in-depth research on the welding behavior of different metal materials.

This article compares laser cleaning with traditional cleaning methods, evaluating their effectiveness, safety, environmental impact, cost, and overall practicality.