Knowledge

The Top Laser Intelligent Manufacturing Expert

First-class R&D team, driving the industry’s technological innovation, the enterprise competitiveness continues to increase

Knowledge

Tired of welding spatter? Learn 5 practical methods to reduce laser welding spatter with STRION LASER’s intelligent equipment. Optimize parameters, enhance gas protection, and achieve clean welds easily.

Would you like me to generate a spatter reduction parameter cheat sheet for common materials and thicknesses, based on STRION LASER’s process packages, for quick reference in your production?

Wondering if handheld laser welding needs skilled operators? STRION LASER breaks the skill barrier with built-in process packages, ergonomic design & stable performance. Learn how novices master welding in 1-2 days, solve welder shortage & boost efficiency.

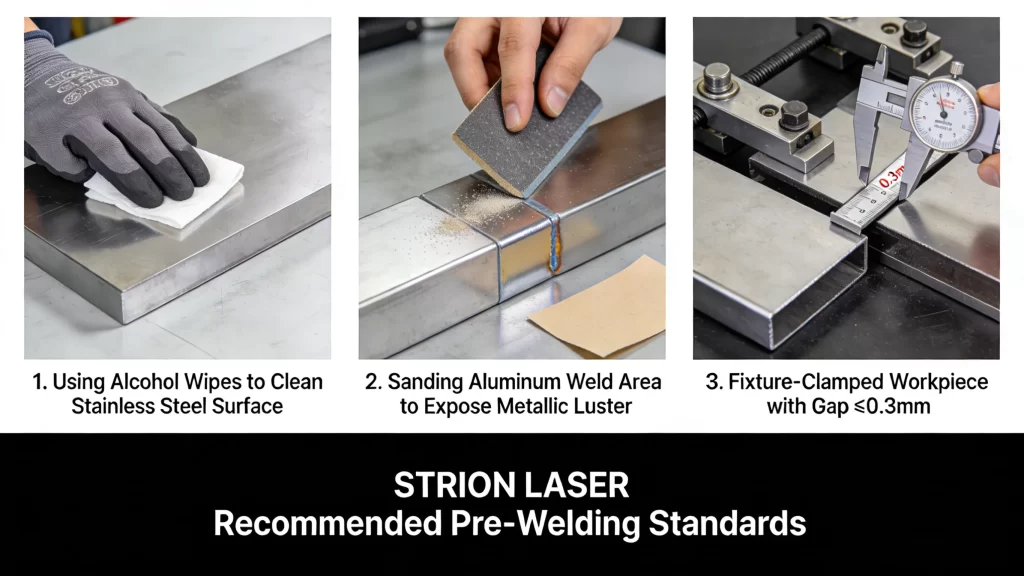

Weak laser welds often result from improper parameters, insufficient penetration, or unstable systems. Learn the real causes of low welding strength and practical ways to improve weld quality in industrial laser welding.

Before purchasing a handheld laser welding machine, buyers should understand welding capacity, stability, operating cost, expandability, and power requirements. This practical guide helps manufacturers choose the right solution based on real production needs.

Choosing a handheld laser welder is not about higher power, but the right match. This guide compares 900W to 3000W handheld laser welders, explains material thickness limits, power requirements, and real application scenarios to help manufacturers make informed decisions.

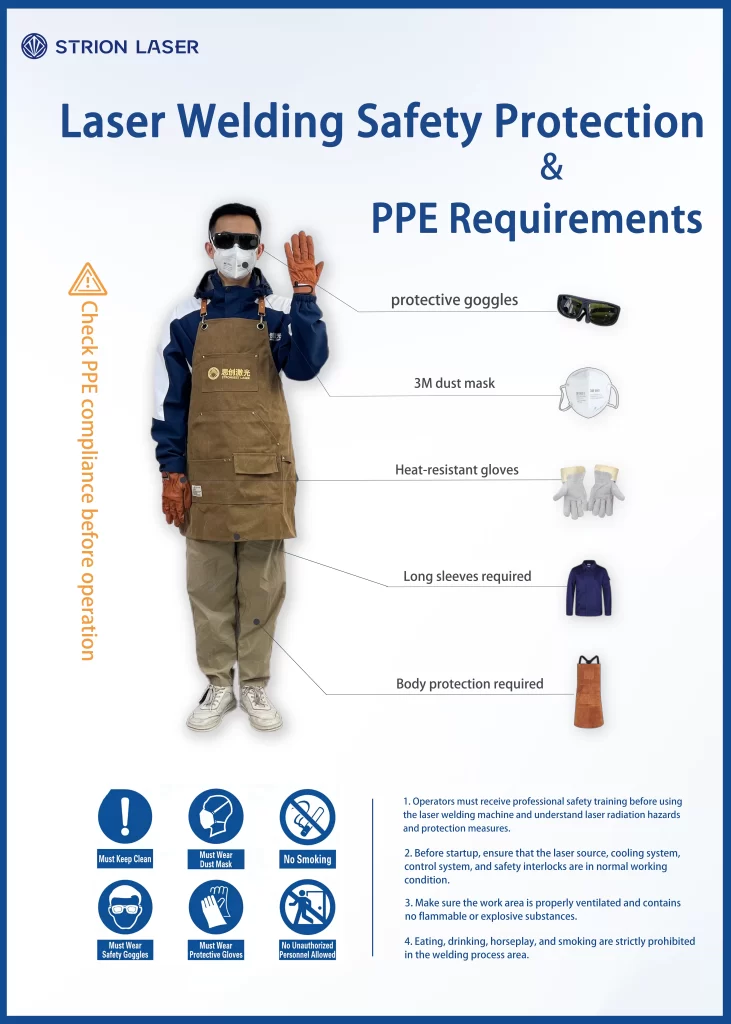

A practical safety guide for handheld laser welding machines. Learn PPE, workspace setup, operation rules, and maintenance tips from STRION LASER.

An objective analysis of whether handheld laser welding machines make sense for small workshops, focusing on efficiency, operating cost, ease of use, and long-term value.

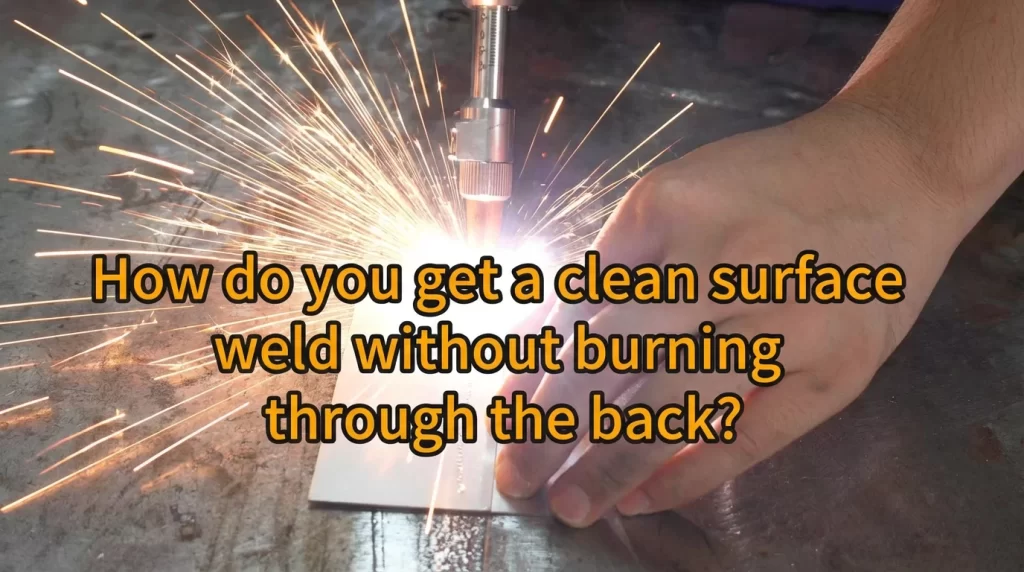

Learn how to achieve clean, bright laser spot welds on 1mm stainless steel with no backside discoloration and reliable strength using precise process control.

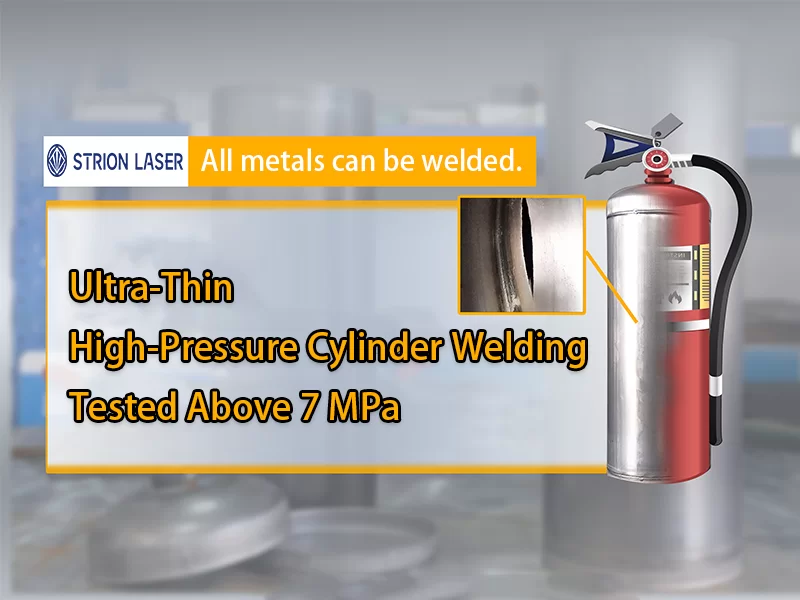

This article explains the welding requirements of fire extinguisher cylinders made of carbon steel, including material properties, pressure standards, and laser welding process parameters for stable, high-strength joints.

A practical comparison of water-cooled and direct-refrigerant laser welding systems, focusing on reliability, maintenance, energy use, and five-year operating costs.