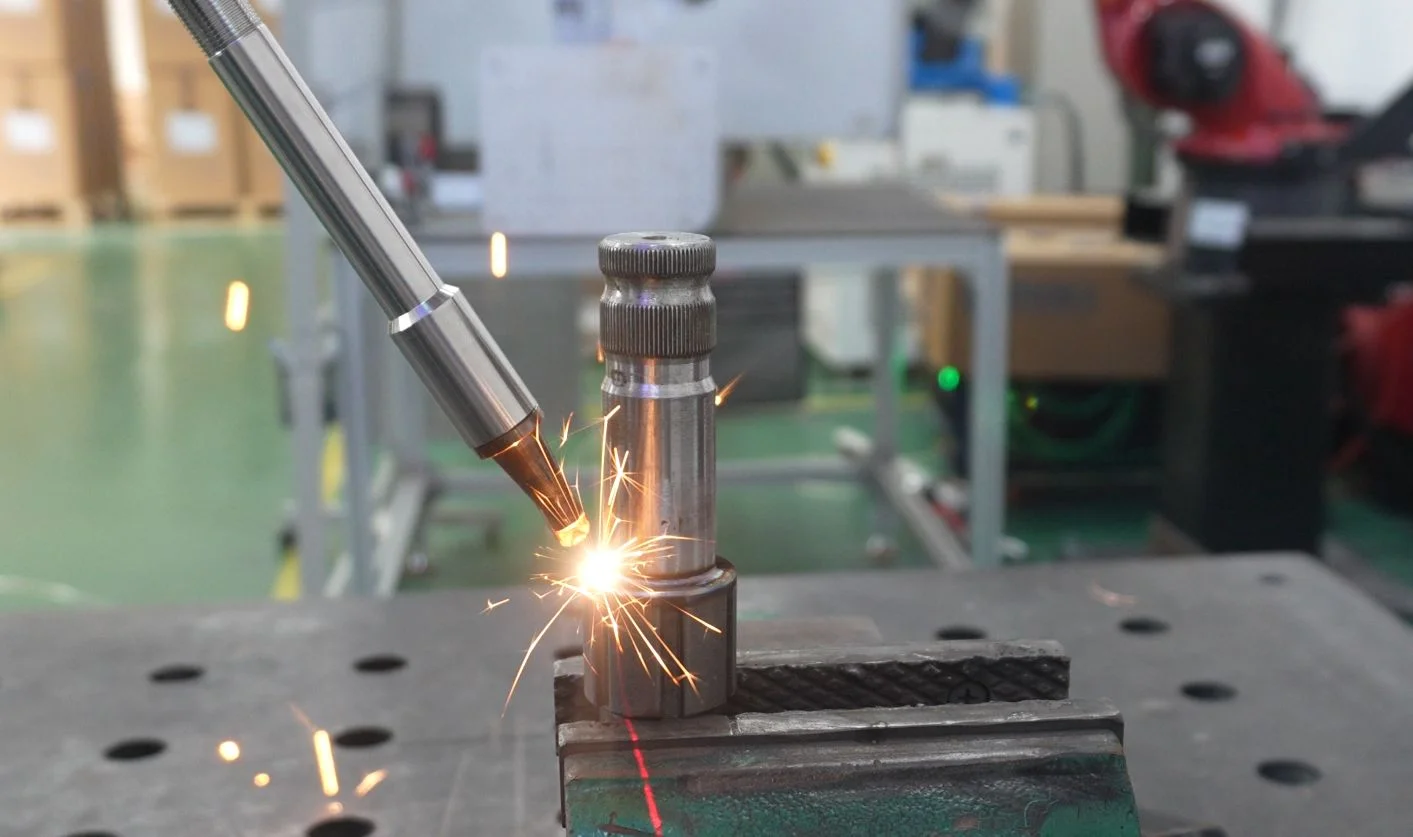

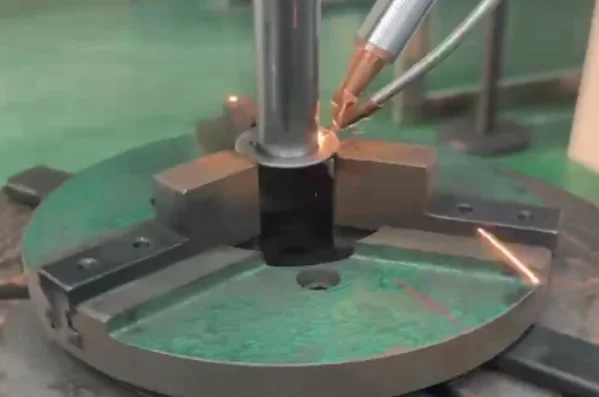

At STRION LASER, we continue to advance the frontiers of industrial welding with our robust and efficient automation systems. Our latest project features automated welding of carbon steel tube-sheet assemblies, delivering high-precision results with exceptional speed and quality.

Application Overview

Material: Carbon Steel

Workpiece Type: Tube-Sheet Welding (Fillet Joint)

Welding Method: Fillet Welding with Wire Feeding

Equipment Used: STRION AW450 / HW350

Welding Time Requirement: Within 5 seconds per joint

Welding Goal: Aesthetic weld seam with minimal crater at arc end

Key Welding Parameters & Techniques

To achieve optimal weld quality, the process hinges on synchronizing positioner rotation speed with wire feeding speed, ensuring uniform deposition and consistent seam formation.

Crater Control: The weld end must slightly overlap the start point by 2–3 mm to eliminate gaps or underfill.

Two Seam Finishing Methods:

Method 1: Controlled arc downslope with light-off at 365° position while allowing the positioner to rotate up to 370°, effectively minimizing arc crater.

Method 2: Maintain laser output 0.5–1s after reaching 370°, allowing weld pool to fill before shutting off, ensuring a full and smooth finish.

Smart Wire Break Control

To prevent excess weld spatter or wire tailing, STRION LASER systems support dual modes of wire breaking:

Method A – Wire Retract Break:

Wire is retracted at the end of the weld. After tuning the feed structure and verifying through dry-run tests, this method works seamlessly with downslope power or final crater-fill pulses.

Method B – Torch Lift Break:

Without retracting the wire, the torch lifts 1 mm while keeping the laser active, causing the wire to melt and break naturally before light-off.

STRION LASER’s automated solutions are engineered for speed, stability, and repeatability, empowering manufacturers to scale up high-volume production while maintaining top-tier welding aesthetics and structural integrity.

Interested in upgrading your welding automation?

Reach out to our team at str@strlaser.com or explore more at www.strlaser-en.com.