Laser technology has revolutionized surface treatment and cleaning methods across industries. Traditional abrasive cleaning techniques, such as sandblasting or chemical treatments, often damage substrates, generate secondary waste, and require extensive downtime. In contrast, the laser cleaning machine has emerged as a cutting-edge solution, offering precision, efficiency, and eco-friendliness.

As industries strive to reduce environmental impact while improving operational efficiency, the adoption of handheld laser cleaning machines and automated laser cleaning systems has accelerated. Below, we explore the major laser cleaning applications across multiple sectors.

1. Industrial Processing

In heavy industries, equipment is exposed to dirt, corrosion, oil, and other contaminants that compromise performance. Laser cleaning machines provide a fast, non-contact solution for removing rust, grease, paint, and oxides from machinery and metal components without damaging the substrate.

Applications include:

Rust removal from pipelines, tanks, and steel structures.

Surface preparation for welding, coating, or adhesive bonding.

Precision cleaning in mold and tool maintenance to extend service life.

Unlike sandblasting, which wears down materials, laser cleaning ensures longevity and minimizes rework costs.

2. Electronics Industry

The electronics sector requires extreme precision in handling sensitive components. Traditional cleaning methods often leave residues or risk static damage. Laser cleaning offers an accurate and residue-free approach.

Common uses include:

Cleaning PCBs (Printed Circuit Boards) by removing oxides or soldering residues.

Connector and contact cleaning to ensure stable electrical conductivity.

Micro-component treatment, where delicate surfaces cannot withstand abrasive methods.

By using a handheld laser cleaning machine, technicians can work flexibly in manufacturing environments without risking contamination.

3. Medical Device Maintenance

Medical equipment must meet strict hygiene and sterility standards. Laser cleaning has become a valuable tool for medical device maintenance because it can eliminate contaminants without harmful chemicals.

Applications include:

Sterilizing surgical instruments by removing biological residues.

Restoring implantable devices without surface degradation.

Cleaning high-value diagnostic equipment, ensuring compliance with safety regulations.

Laser cleaning is a safer alternative compared to chemical sterilization, which may leave residues or damage sensitive surfaces.

4. Manufacturing Lines

In automated production environments, downtime is costly. Laser cleaning machines can be integrated into production lines to keep equipment free of buildup, contamination, or coatings that reduce efficiency.

Examples include:

Rubber mold cleaning in tire manufacturing, ensuring consistent product quality.

Removal of lubricants and oils from conveyor systems or tooling.

Surface preparation for automated coating and painting processes.

Because lasers work quickly and without consumables, they reduce maintenance costs and improve line productivity.

5. Automotive Sector

The automotive industry demands precise cleaning solutions for both manufacturing and maintenance. Laser cleaning machines are increasingly used in areas where traditional abrasive methods are inefficient or risky.

Applications include:

Rust removal from vehicle frames and components without weakening the metal.

Paint and coating stripping for refurbishment or reprocessing.

Weld seam cleaning, ensuring strong, defect-free bonds.

Brake pad and engine part cleaning, improving safety and performance.

A handheld laser cleaning machine is particularly useful in automotive workshops, where flexibility and precision are required.

6. Cultural Relics & Artwork Restoration

One of the most delicate applications of laser cleaning lies in the preservation of historical artifacts. Traditional cleaning methods risk damaging fragile cultural relics, while chemicals may irreversibly alter surfaces.

Laser cleaning provides a controlled, non-invasive method to remove contaminants like dirt, soot, and biological growth. Applications include:

Restoring stone sculptures without chipping or erosion.

Cleaning frescoes and paintings by gently removing surface pollutants.

Conserving metallic artifacts, such as bronze statues or ancient coins.

Because the process is highly precise, curators and restorers can adjust laser parameters to suit each artifact’s material and sensitivity.

7. Aerospace Engineering

The aerospace industry demands precision, safety, and efficiency in maintenance processes. Laser cleaning has become an essential tool for preparing and maintaining aircraft components.

Applications include:

Coating removal from turbine blades without altering their aerodynamic performance.

Oxide and corrosion removal from aluminum and titanium components.

Surface preparation for bonding and painting, ensuring durability in extreme conditions.

By eliminating the need for abrasive blasting or chemical stripping, laser cleaning ensures both efficiency and compliance with strict aerospace regulations.

8. Marine and Shipbuilding

The marine sector faces constant challenges from corrosion, biofouling, and coating buildup due to harsh seawater environments. Laser cleaning machines offer a practical solution for ship maintenance and construction.

Applications include:

Rust and paint removal from hulls, decks, and structural components.

Biofouling removal (barnacles, algae, etc.) without toxic antifouling chemicals.

Engine and mechanical part cleaning to restore efficiency and prolong service life.

Unlike sandblasting, which produces hazardous dust, laser cleaning is environmentally friendly and requires minimal safety precautions.

Advantages of Laser Cleaning Across Industries

The widespread adoption of laser cleaning technology is driven by its unique advantages:

Non-contact method: No wear and tear on the substrate.

Eco-friendly: No chemicals or abrasive waste generated.

High precision: Adjustable laser parameters for different materials.

Cost-effective: Reduced downtime, consumable-free, and longer equipment lifespan.

Versatility: From industrial heavy-duty rust removal to delicate artifact restoration.

Conclusion

The applications of laser cleaning machines span a remarkable range of industries, from heavy-duty industrial processing to delicate cultural restoration. As industries move toward more sustainable and efficient practices, the demand for handheld laser cleaning machines and automated solutions will only continue to grow.

If your business is exploring advanced surface treatment solutions, working with a trusted laser cleaning machine manufacturer ensures reliable technology, training, and long-term support.

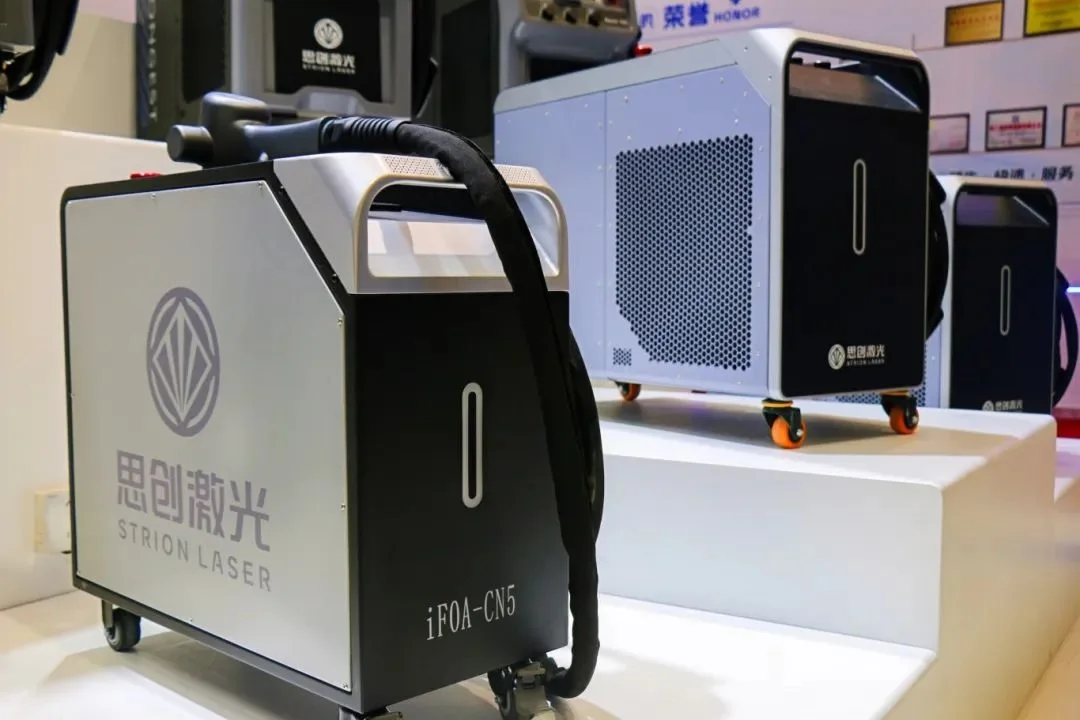

For innovative and industry-leading solutions in this field, STRION Laser laser welding manufacturer provides high-quality laser cleaning machines designed to meet the diverse needs of modern industries.