Hybrid welding technology is particularly important in the shipbuilding industry to cope with the complexity and large size requirements of ship structures and to improve the efficiency and quality of ship construction.

Laser hybrid welding

Redefine the Performance of Laser Welding

Automated laser hybrid welding

NON-FERROUS METAL WELDING EXPERTS

You have a thick-walled component and wish to automate your production? If so, laser hybrid welding with the STRONGEST LASER laser hybrid welding is the perfect choice. The innovative design enables optimal adaptation to the specific application – particularly due to its high flexibility and the integrated sensors.

The advantages: Laser hybrid welding

By combining the advantages, the hybrid technology avoids the disadvantages that the individual processes entail. Laser hybrid welding offers you:

- Higher welding speeds

- Improved seam quality

- More stable processes

- Lower thermal distortion or the component

Welding Video Cases

Welding Video Cases

CLOSE

Project Cases

Project Cases

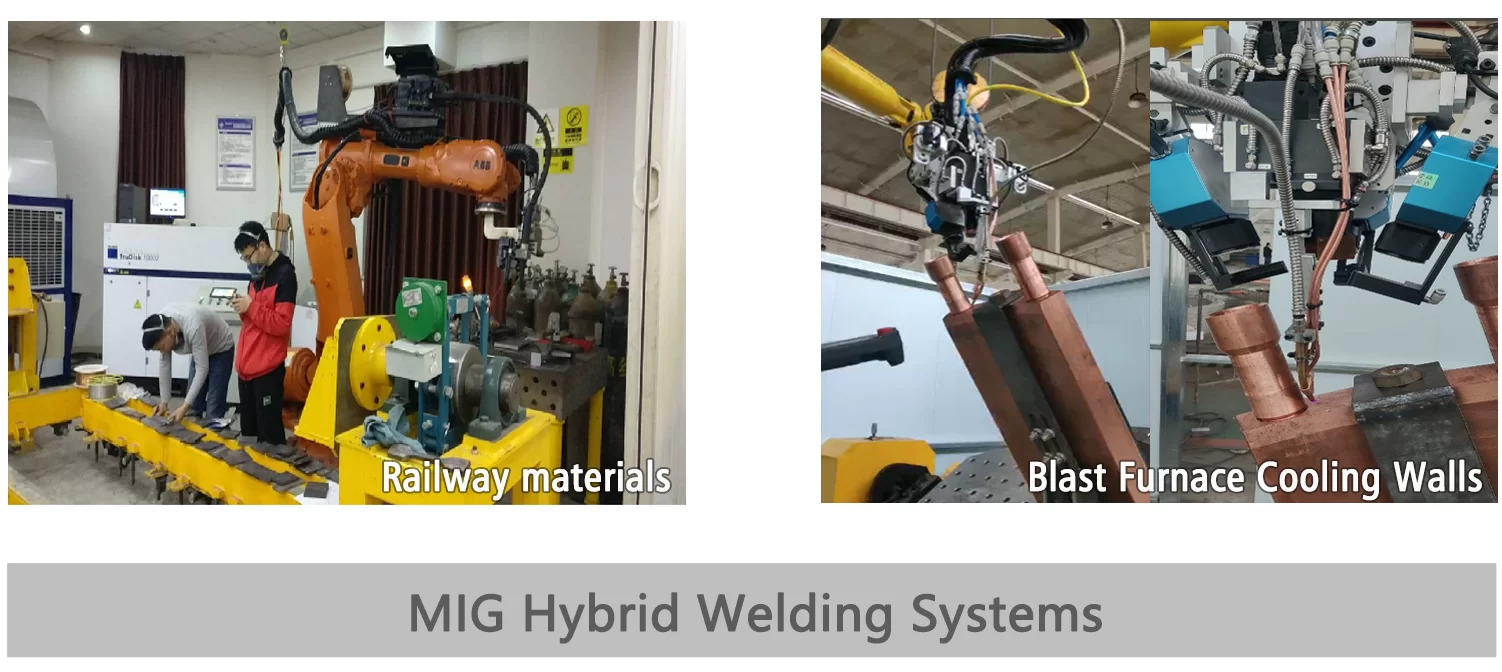

MIG Hybrid Welding Systems

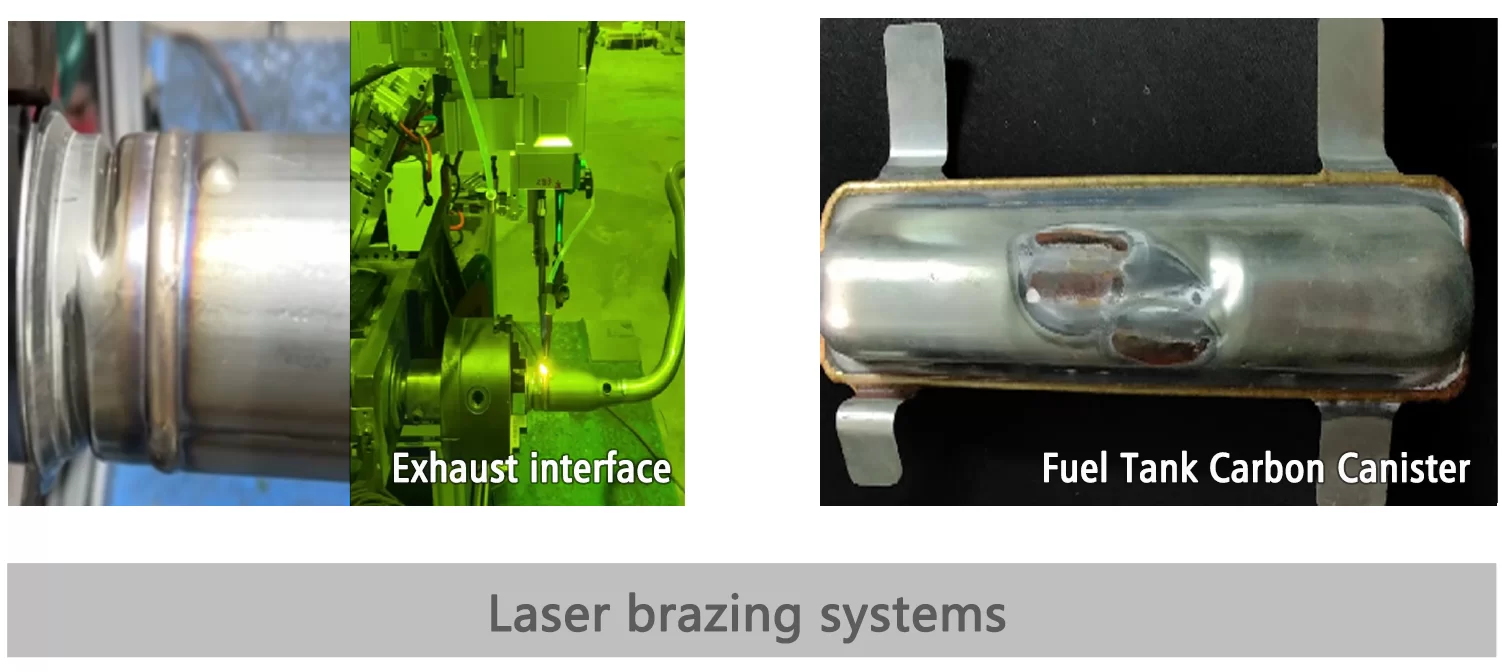

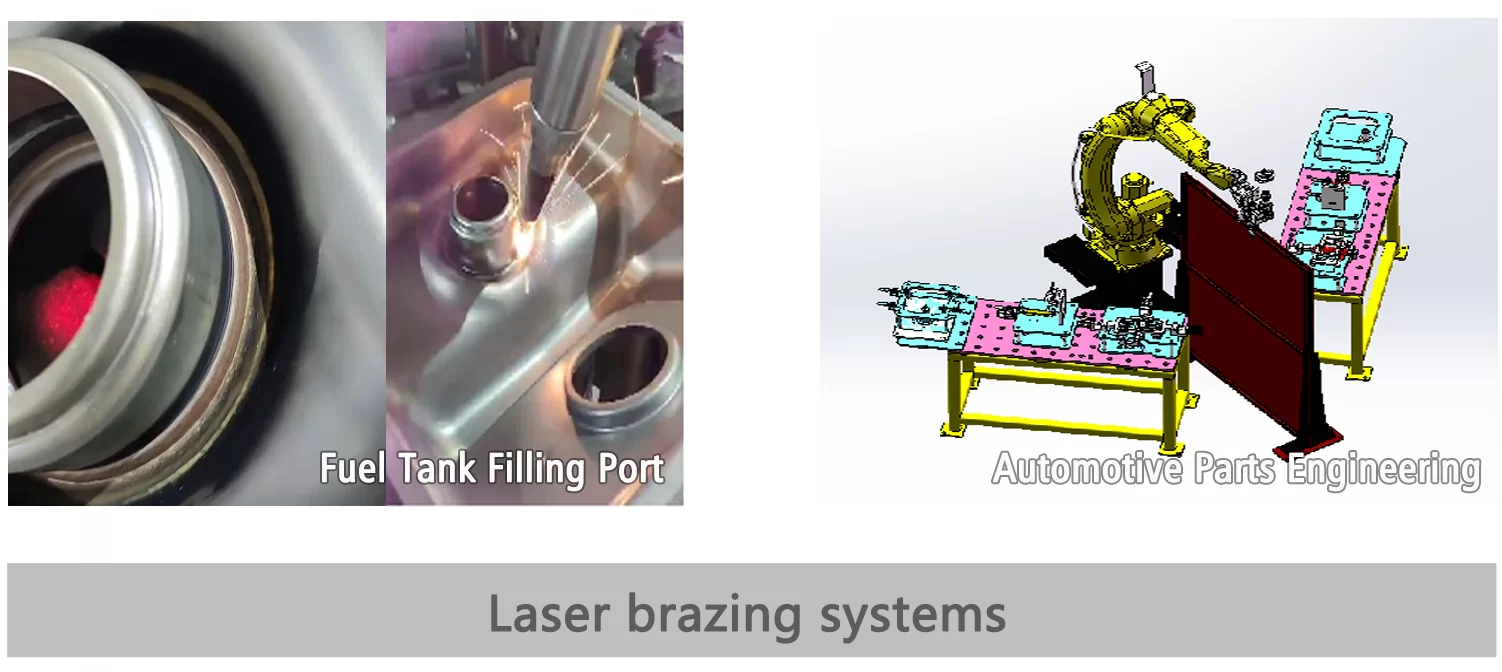

Laser brazing systems

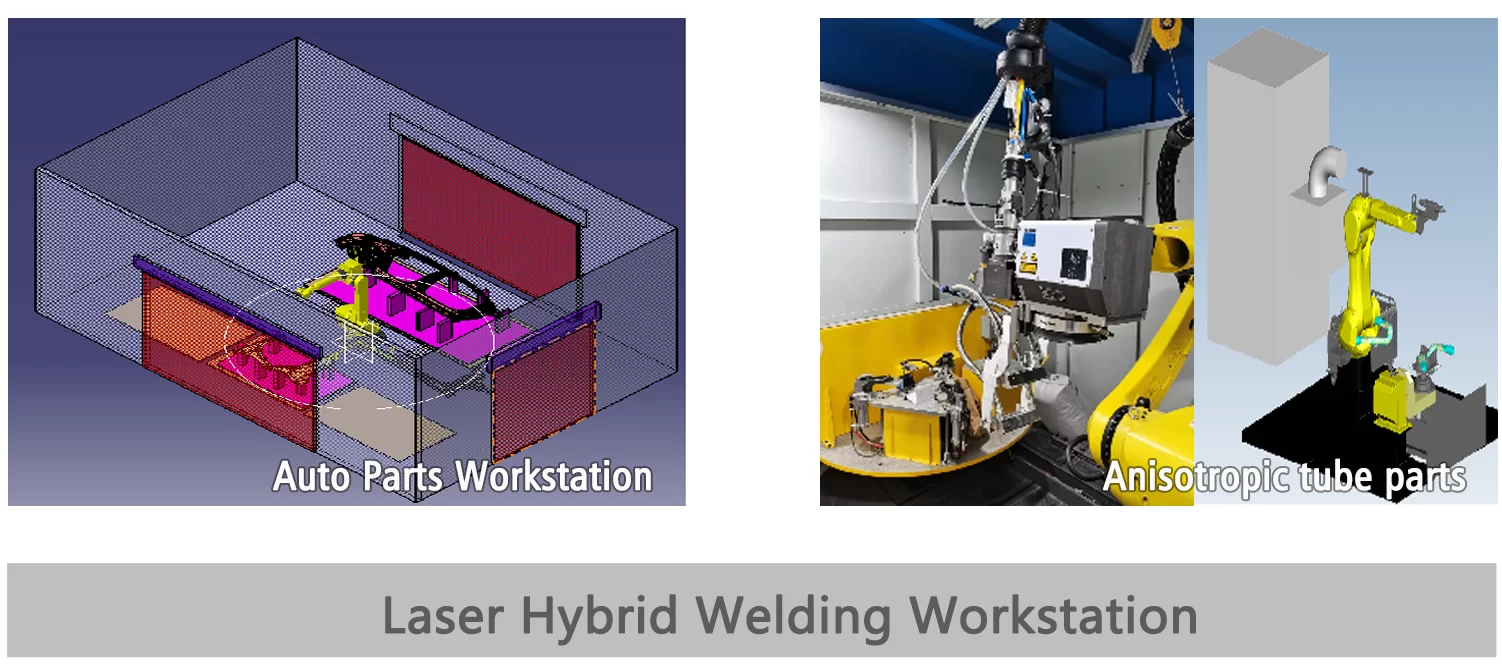

Laser Hybrid Welding Workstations

CLOSE

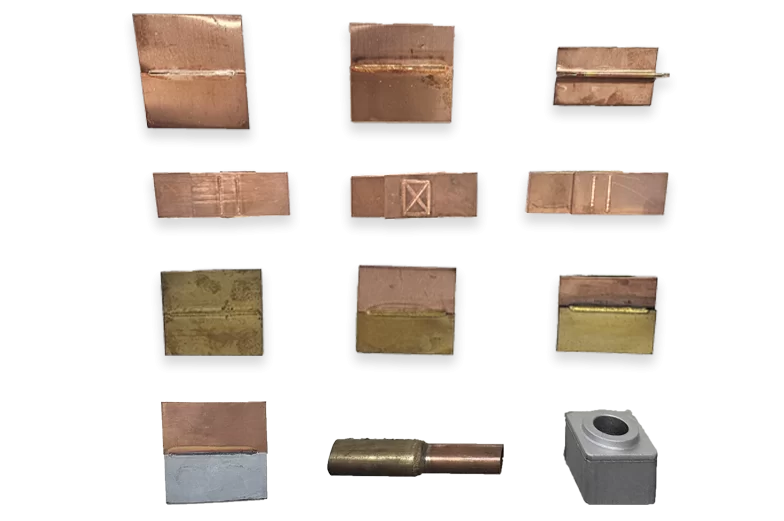

Welding Samples

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Application Industries

Laser hybrid welding Are Everywhere,

with More to Come

Shipbuilding IndustryIntelligent Manufacturing for Ships

Rail Transit IndustryCombined laser-MIG/MAG arc welding, two in one

For rail transport, composite welding technology can provide an efficient welding method to ensure the strength and safety of train components and improve the stability and safety of train operations.

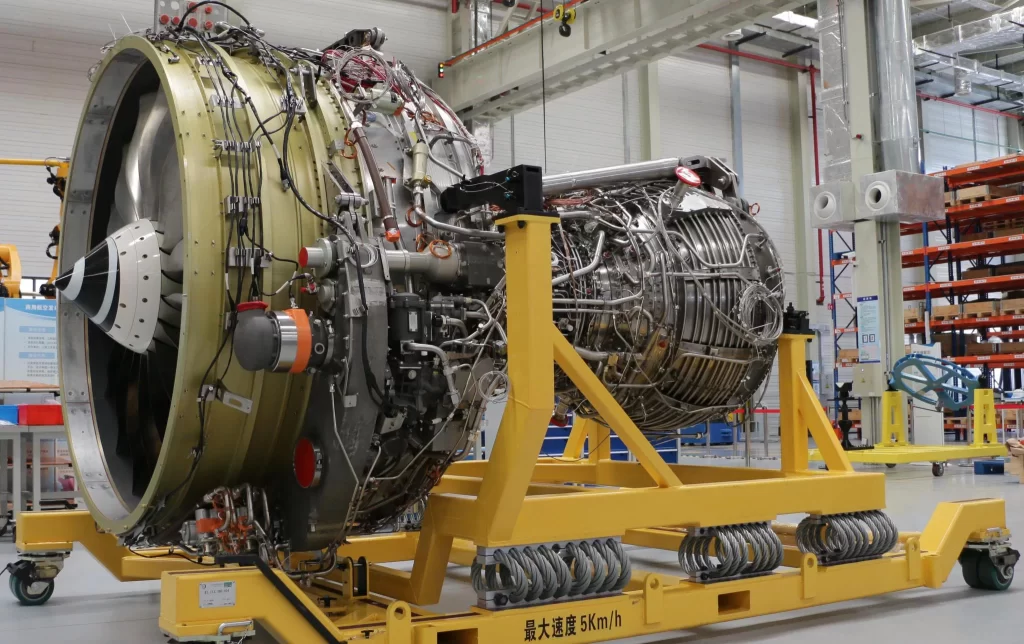

AerospacePrecision Laser Welding Technology

In the aerospace field, composite welding technology is widely used in the manufacture of aircraft structures due to its high efficiency and high quality welding capability, which can meet the high standards and strict requirements of aviation materials.

Structural Steel IndustrySolving complex structural fabrication

In the field of steel construction, composite welding technology provides high-quality welded joints that improve the overall performance and durability of steel structures.

CLOSE

Frequently Asked Questions

Frequently Asked Questions

laser-hybrid-welding

What is Laser hybrid welding?

Laser hybrid welding combines the advantages of laser welding with those of arc welding. This welding process is becoming particularly established in shipbuilding, automotive production and rail vehicle construction.

Can Strongest Laser weld materials of different thicknesses and metals?

Sure, different types of metals (such as copper and stainless steel or aluminum) can be easily welded together.

What are the process advantages of laser hybrid welding?

Laser hybrid welding combines the advantages of both processes, allowing high weld depths and high gap bridging at the same time, and is particularly suitable for high thickness materials. The filler material can also have a positive effect on the properties of the weld.

Want customized solutions?

With our expertise and experience in welding, we are happy to advise you and work with you to find the perfect solution for your specific welding requirements. Please contact us.

CLOSE