Laser welding of stainless steel locomotive body is the process of laser welding the stainless steel skin and internal framework of the locomotive from the inside out. Unlike traditional welding, it does not allow welding marks and thermal deformation to appear on the outer surface of the skin, but requires high aesthetic appearance, similar to “scar-free stitching”. This welding method is widely used in locomotive manufacturing in developed countries such as Europe, America, and Japan, and has become one of the important technologies in manufacturing new models of high-end locomotives.

Handheld Laser WeldIng Machines

Redefine the Performance of Laser Welding

Handheld Laser Welding Machines

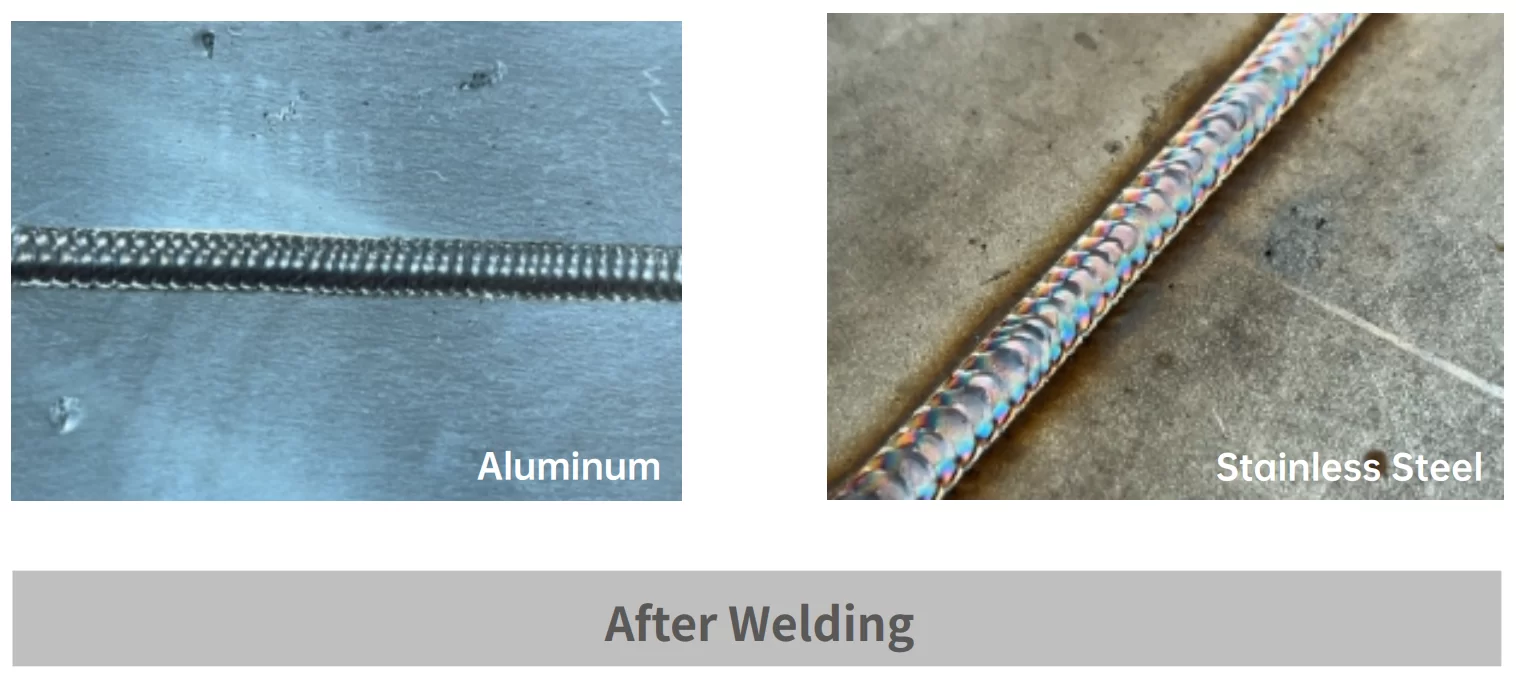

All metals can be welded

Laser welding is a high-efficiency precision welding method that uses a high energy density laser beam as a heat source.Laser welding is one of the important aspects of the application on laser material processing technology.

STR-HW Series - Handheld laser welder

Laser welding is a high-efficiency precision welding methodthat uses a high energy density laser beam as a heat source.Laser welding is one of the important aspects of the application on laser material processing technology.

- 3 in 1 Function: Laser welding, Laser cutting, Laser cleaning

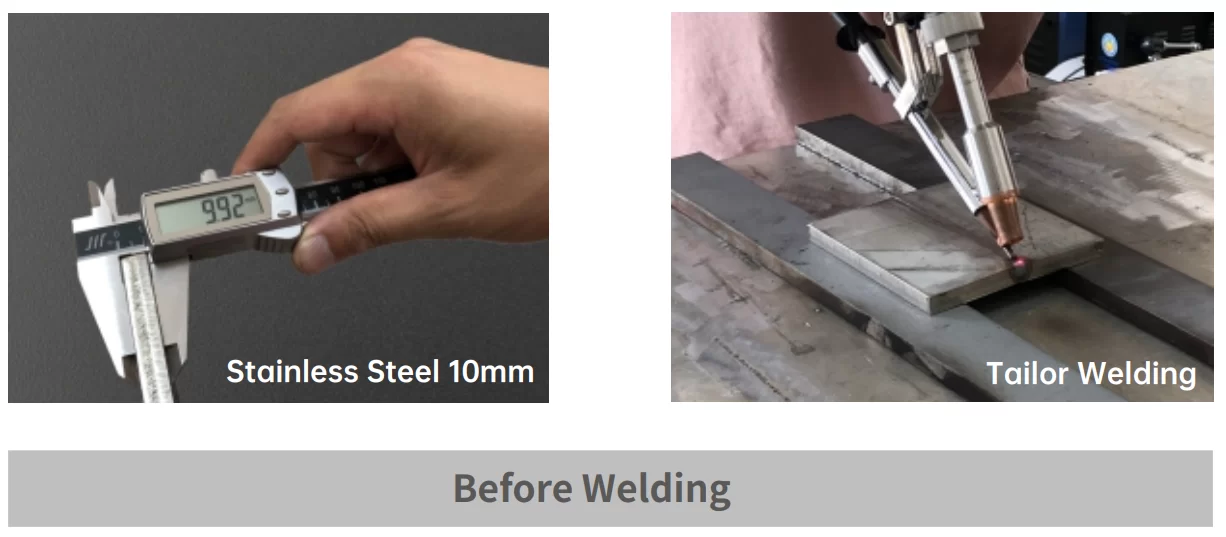

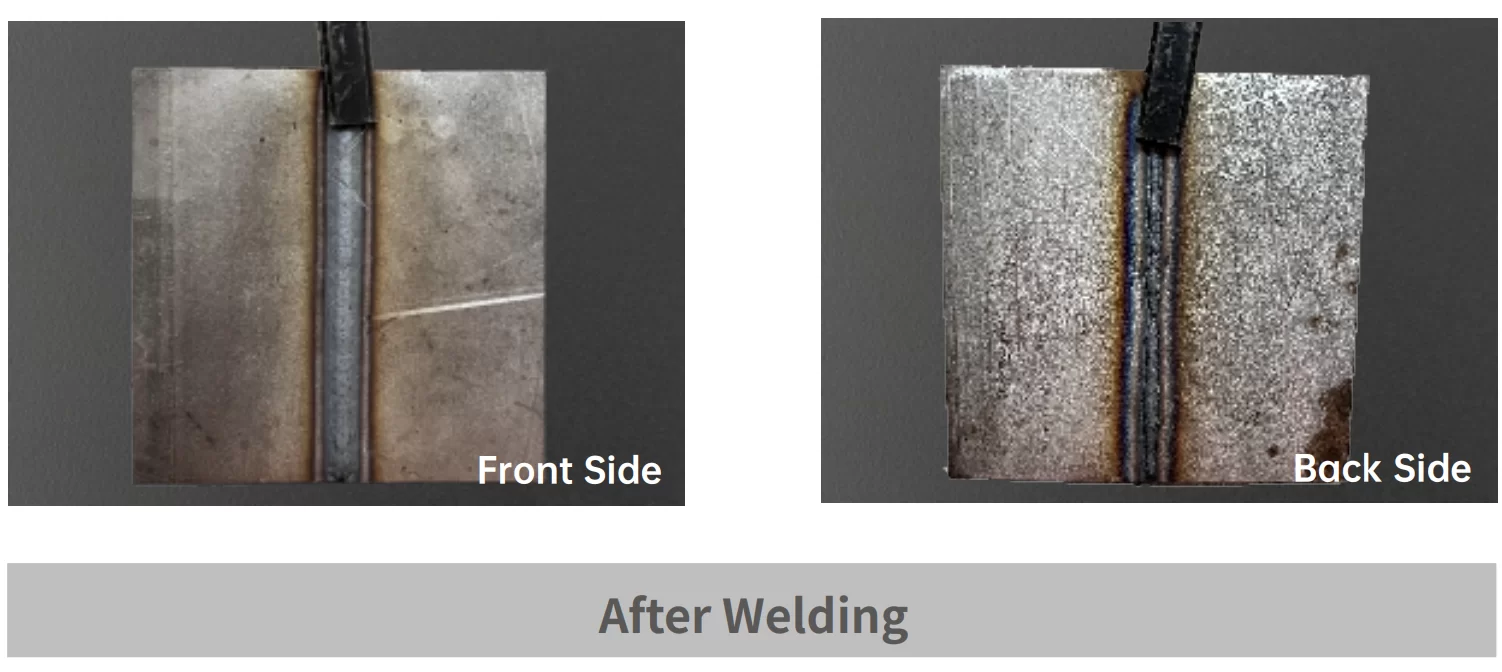

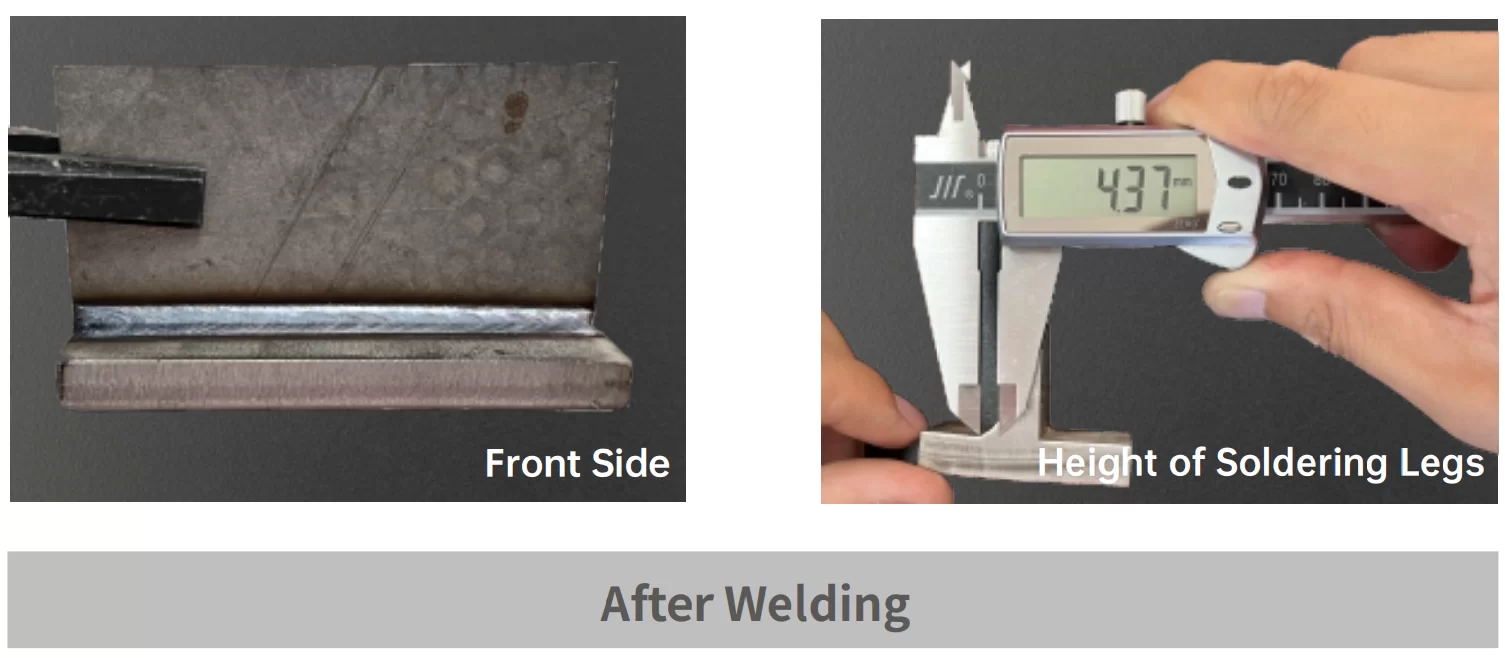

- Max. Penetration 10mm , max. Width 10mm

- Sing-wire, Double-wire are available

Welding Video Cases

Welding Technology

Welding Technology

Penetration Welding

Penetration Welding

Penetration Welding

CLOSE

Process Diagram Collection

Process Diagram Collection

CLOSE

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Fiber Laser Welding Solutions Are Everywhere, with More to Come

Fiber Laser Welding Solutions Are Everywhere,

with More to Come

Vehicle manufacturing:body manufacturing of subway/high-speed rail rolling stocks

Medical Instruments: a failure could mean a life!

Products within the medical industry require the highest levels of precision. It is incredibly important that they meet the highest quality demands. The size of many medical devices and products are continually decreasing. This is where lasers are perfect as they are perfectly suited for creating equally minute weld seams. Even in complicated areas, laser weld spots and seams can easily be generated to provide sterile surfaces with no post-processing.

Electronic communication: electronic components - special welding

Electronic parts and components includes electronic components and parts of small machines and instruments, which are often composed of several elements and can be widely used in similar products; It is a general term that often refer to certain components in industries such as electrical appliances, radios, instruments, etc., such as capacitors, transistors, hairsprings, springs, and other sub devices. Laser welding features fast welding speed, large depth to width ratio, small deformation, and high density. It is a welding process that utilizes laser action to melt metal surface instantaneously and thus connects the metal. It belongs to non-contact processing method, and therefore does not produce mechanical extrusion or stress, making it especially in line with the processing requirements of the electronic industry.

Hardware products and building materials: hardware products, building materials

Laser welding can find its wide welding and automated integration applications in such segmented fields as platinum rhodium alloy nozzle plates of bushing for producing fiber glass, relays, elevator panels, washing machines, dishwashers, smoke exhaust ventilators, microwave ovens, water cups, refrigeration valves, and solar panels.

Furniture and electrical appliances: various stainless steel furniture

For welding metal furniture and electrical appliances, handheld laser welders are usually adopted to weld cabinets such as filing cabinets, safes, bookshelves, explosion-proof cabinets, etc., and electrical appliances such as refrigerators, air conditioners, insulated kettles, hot water kettles, etc., due to the fact that handheld laser welders have the multiple merits, including fast speed, sound and visually pleasing welds, and can greatly save labor costs caused to enterprise users, improve efficiency, and deliver effective and complete solutions. The intelligent operation mode makes welding faster.

Automotive Technology: Components of Automotive suppliers

Laser welding utilizes high-energy density laser beam as a heat source to irradiate the connection location where a joint will be formed two separated work pieces, causing the separated material to quickly melt and even vaporize after absorbing laser energy, and form a molten pool that in the subsequent cooling process will solidifies, causing the two work pieces to join together. Due to the characteristics of concentrated heating zone that can be precisely controlled, small welding deformation and fast welding speed, laser welding is becoming increasingly popular among automotive suppliers.

CLOSE