Hybrid welding technology is particularly important in the shipbuilding industry to cope with the complexity and large size requirements of ship structures and to improve the efficiency and quality of ship construction.

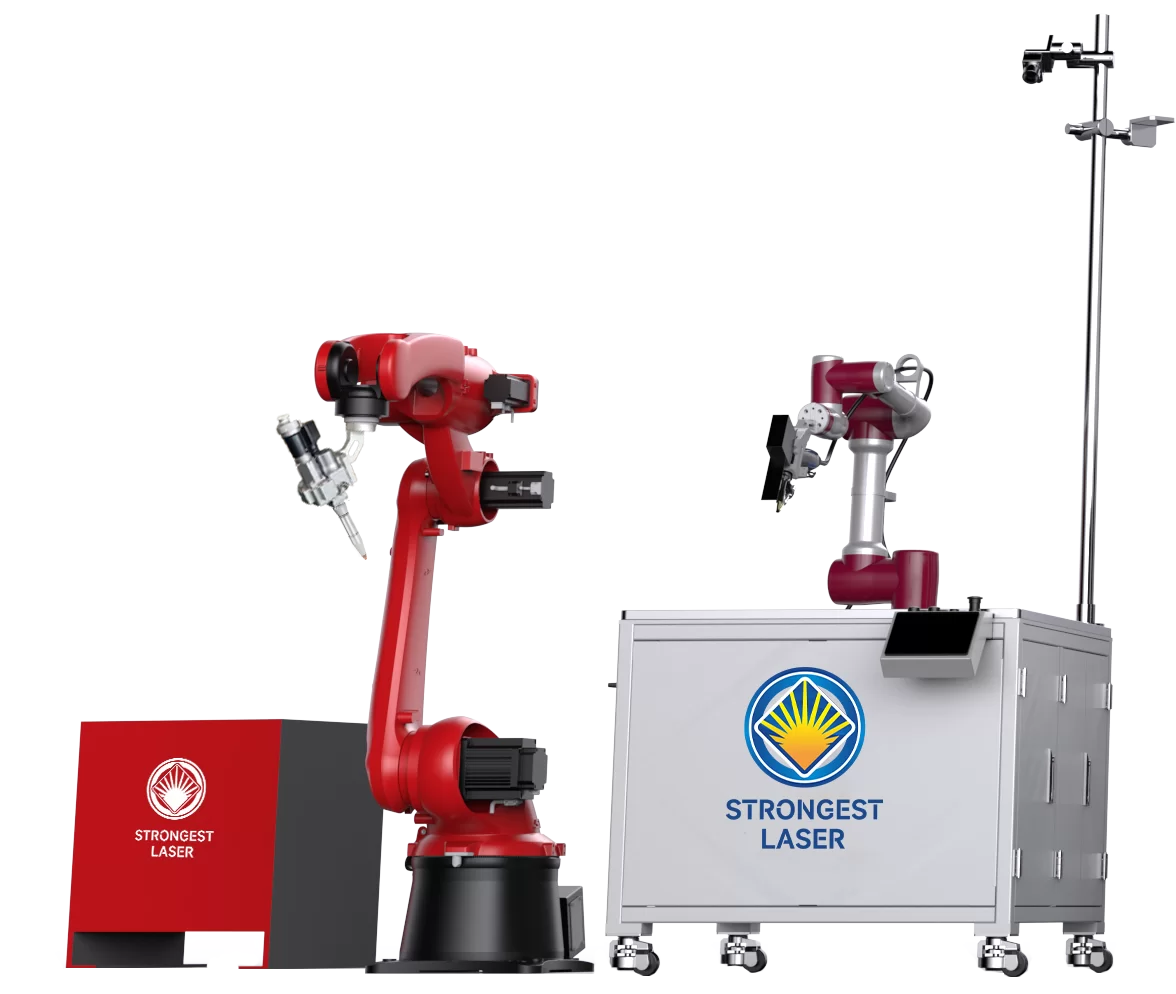

Automated Welding Solution

Redefine the Performance of Laser Welding

Automated Welding Solution

Flexible, user-friendly and cost effective

Welding robots has emerged as a game-changer, offering unparalleled advantages in terms of productivity, quality, and cost-effectiveness for various heavy industries. At STRION LASER, we specialize in delivering innovative welding robots tailored to meet your specific needs. Explore how our cutting-edge technologies can streamline your welding operations and propel your business to new heights.

The advantages: Automated Robotic Welding

With advanced robotic welding solutions you are capable of reaching otherwise inaccessible locations and can perform complex and precise weldings and welds more quickly compared to manual welding. It allows time for manufacturing and also for more flexibility.

- Shorter Deployment Time

- Improved Quality & Productivity

- Safer Production Line

- Responsive to Various Needs

STRION LASER Automated Robotic Laser Welding Advantages

Advantages of the STRION LASER automated laser welding

Easily weld a variety of thick, thin, and dissimilar metals

Conventional Robotic laser Integrated Welding | STRION LASER Automated Solutions | |

| Process Demonstration | The vast majority of integrated manufacturers do not understand laser welding and do not have process guidance | STRION LASER welding process kit, poured into the robot system, control of the entire welding process by means of a teach pendant |

| Digital Communications | The vast majority of laser welding machines on the market are analogue controlled, with delays and inaccuracies in communication with the robot. | STRION LASER digital communication, fully adapted to the robot, with mutual software matching, greatly reducing the difficulty of use. |

| After-sales Service | After-sales service process, due to all assembled products, a load of problems, easy to produce disputes and other phenomena, the service is not timely | Integration of after-sales service to jointly solve customer problems |

CLOSE

Automated Welding Video Cases

Customer Solutions for Welding Automation

Customer Solutions for Welding Automation

Cabinet Standard Automated Robot Welding

- Characteristics: Robotic welding system for welding Cabinet made of sheet metal in varying thicknesses.

- Material: Al.

- Customer Pain Points: High workplace injury occurrence leads to welding related jobs to be unpopular, making recruitment difficult.Dirty and poor working condition is physically demanding for workers.

Electric Vehicle Gears Automated Welding

- Characteristics: Robotic welding system for a wide range of tasks and components, which is cost effective even for small batch sizes.

- Material: Steel, carbon steel, Al.

- Customer Pain Points: Difficulty finding skilled welding professional.Has a tough time finding the right equipment to weld different materials.

Pipe, frames and various other components

- Characteristics: Compact robotic welding system for various components, cost effective from a batch size of one.

- Material: Steel, carbon steel, Al.

- Customer Pain Points: Finding the appropriate welding machine for welding materials can be difficult, while being expensive to deploy.

CLOSE

Welding Samples

Become Our Distributor

Why become our distributor?

Benefit from our experts’ advice to meet your brand’s needs.

Product & Pricing Support

- High-performance laser welding equipment – including handheld, hybrid, and robotic systems

- Competitive distributor pricing – ensuring attractive profit margins.

- Customized product recommendations – tailored to different industry needs.

- Demo machine support – for marketing and customer demonstration

Marketing & Brand Empowerment

- Authorized use of our brand – legally use trademarks and branding materials.

- Exclusive territory protection – avoid price wars and protect your market.

- Exhibition and promotion support – marketing materials and event cost subsidies

- Joint promotion on our official website and social media – increase your local visibility

CLOSE

Application Industries

Laser hybrid welding Are Everywhere,

with More to Come

Shipbuilding Intelligent Manufacturing for Ships

Transportation Intelligent manufacturing of tracks, bridges, etc

Laser automatic welding technology can provide an efficient welding method, ensuring the strength and safety of tracks and bridges, and improving stability and safety during use.

Aerospace manufacturing Precision laser welding technology

In the aerospace field, laser welding technology is widely used in the manufacturing of aircraft structures due to its efficient and high-quality welding capabilities, which can meet the high standards and strict requirements of aviation materials.

Automotive Technology Repair of Car Doors

Laser welding utilizes high-energy density laser beam as a heat source to irradiate the connection location where a joint will be formed two separated work pieces, causing the separated material to quickly melt and even vaporize after absorbing laser energy, and form a molten pool that in the subsequent cooling process will solidifies, causing the two work pieces to join together. Due to the characteristics of concentrated heating zone that can be precisely controlled, small welding deformation and fast welding speed, laser welding is becoming increasingly popular among automotive companies.

CLOSE