3D printing technology can be utilized to print some molds with intricate internal structure that are impossible to be created through casting or machining. Moreover, the complexity will not incur additional costs as long as it meets the construction range of 3D printers and. This enables mold manufacturers to better control mold temperature, reduce rejects, shorten cycle time, improve dimensional stability and surface finish, and facilitate demolding.

Additive Manufacturing (3D printing)

STR-AM SERIES ADDITIVE MANUFACTURING LASER LIGHT SOURCE

Additive Manufacturing (3D printing)

STR-AM SERIES ADDITIVE MANUFACTURING LASER LIGHT SOURCE

3D printing usually adopts digital material printers. In mold manufacturing, industrial design, and other fields, it is often used to create models and is gradually applied to direct manufacturing of some products. This technology has already been used to produce components and has found applications in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aviation and space, dental and medical industries, education, geographic information systems, civil engineering, and other fields.

STR-AM Series -Fiber Lasers for Additive Manufacturing

The hardware and software interfaces of this series of lasers provide strong compatibility, and can be used as the functionally-identical alternative items for similar products and functional expansion of relevant platforms.

- Annual Power Attenuation Rate <1%

- Up to 52% efficiency of electro-optical conversion of the whole machine

- Adjustment Response Speed <10μs / Response Accuracy <2μs

Industry Applications:Selective laser melting

Industry Applications :Selective laser melting

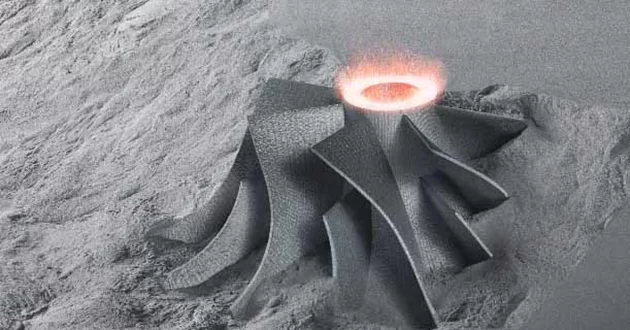

SLM-Selective laser melting

SLM technology is the process of selectively melting metal powder layer by layer under the action of high-energy laser. After heat dissipation and solidification, it is metallurgically welded to the base metal, and then stacked layer by layer to form a three-dimensional solid with metallurgical bonding and dense structure.

SLM can directly produce metal parts from three-dimensional solid models without the need for molds, greatly shortening the product development cycle and reducing development costs for complex metal parts.

SLM materials mainly include cobalt alloys, nickel alloys, steel, aluminum alloys, and biomedical alloys. Metal powders are mainly atomized spherical powders with particle sizes ranging from 10 to 50 μ m. The SLM process has a processing layer thickness of 20~120 μ m, and the accuracy is generally 0.05~0.1mm.

SLM technology products are widely used in aerospace, automotive, home appliances, molds, industrial design, medical biology, and other fields.

CLOSE

Fiber Laser Solutions Are Everywhere, with More to Come

Fiber Laser Solutions Are Everywhere with More to Come

Mold manufacturing

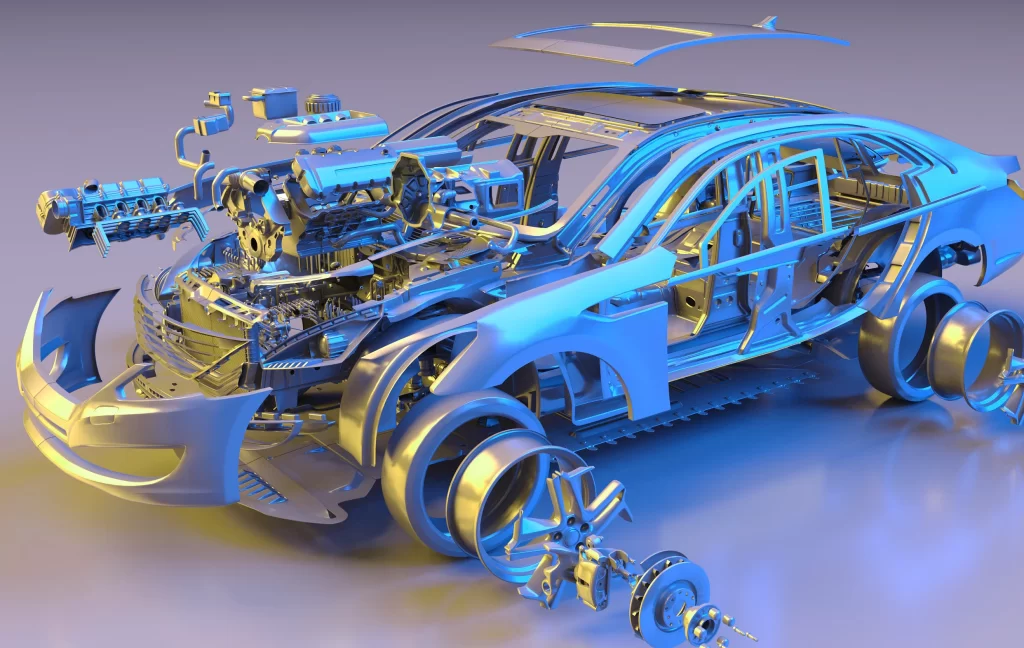

Automotive manufacturing

The application of 3D printing technology in the automotive industry has made significant progress, and even mass production of some automotive components has been realized. Although 3D printing of an entire car is still unrealistic at present, it has shown extraordinary significance for the entire automotive industry production system. It may be one of the key pillars supporting the future automotive revolution

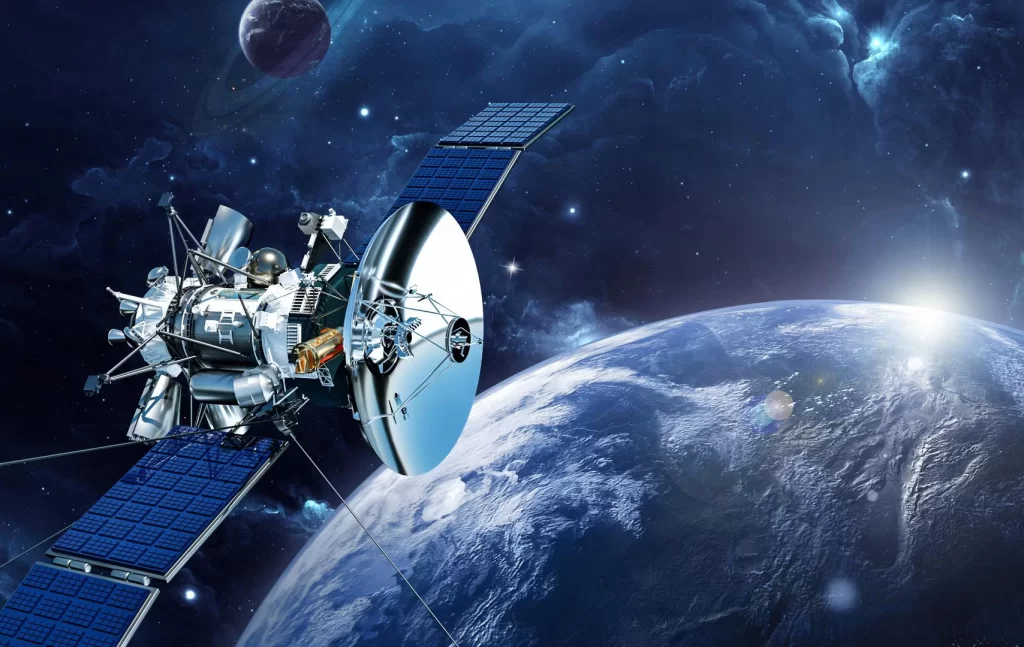

Aviation and space

Laser additive manufacturing provides a new process approach for the design and manufacturing of high-performance metal components, which can solve new challenges related to materials, structures, processes, performance, and applications in research and development activities in the fields of aviation and aerospace.

Medical field

There are a large number of customized needs in modern medical industry that are difficult to be satisfied through standardized and mass production. 3D printing technology can customize exclusive medical auxiliary devices for patients based on their needs from time to time, such as postoperative repair protectors, crutches, etc; 3D printing can also assist doctors in treatment, such as preoperative models, printing high-precision medical devices, etc; High precision 3D printers can find its applications in clinical surgeries such as orthopedics, plastic surgery, and surgery; and dental correction and restoration in the field of dentistry.

CLOSE

2-1724987578.webp)